Enhancing Concrete Countertop Creation with Vibrating Tables

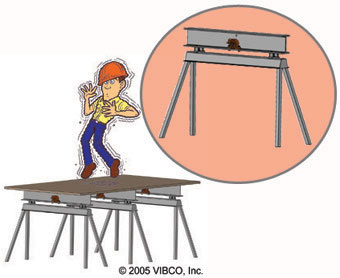

Vibrating tables are essential tools in the creation of concrete countertops, providing a method for removing air bubbles and ensuring a smooth, uniform finish. These tables consist of a flat surface mounted on springs or other mechanisms that generate vibrations when activated. When pouring concrete into molds for countertops, air bubbles can become trapped within the mixture, leading to imperfections such as voids, pinholes, and uneven surfaces. Vibrating tables help to eliminate these imperfections by agitating the concrete mixture, causing air bubbles to rise to the surface and escape.

The vibrating action of the table also helps to distribute the concrete evenly within the mold, ensuring a consistent thickness and density throughout the countertop. This results in a smoother and more uniform finish that is free from imperfections. Additionally, vibrating tables can help to reduce the risk of cracking and shrinkage in the finished countertop by compacting the concrete mixture and removing excess air.

Benefits of Using Vibrating Tables

There are several benefits to using vibrating tables in the creation of concrete countertops. One of the primary benefits is improved consistency and quality of the finished product. By removing air bubbles and ensuring even distribution of the concrete mixture, vibrating tables help to create countertops that are smoother, more uniform, and free from imperfections.

Another benefit of using vibrating tables is increased efficiency and productivity. Vibrating tables can help to speed up the curing process by compacting the concrete mixture and removing excess air, allowing for faster demolding and finishing of the countertops. This can help to reduce production time and costs, making vibrating tables a valuable investment for concrete countertop manufacturers and fabricators.

Types of Vibrating Tables

There are several types of vibrating tables available for use in the creation of concrete countertops, ranging from small, handheld models to large, industrial-sized tables. Handheld vibrating tools are typically used for smaller countertop projects or touch-up work on larger countertops. These tools are portable and easy to use, but may not provide the same level of vibration intensity as larger tables.

Industrial-sized vibrating tables are larger and more powerful, capable of accommodating multiple molds simultaneously and providing higher levels of vibration intensity. These tables are ideal for large-scale countertop production and can help to maximize efficiency and productivity. Additionally, some vibrating tables are equipped with variable speed controls, allowing users to adjust the intensity and frequency of the vibrations to suit their specific needs.

Tips for Using Vibrating Tables

When using vibrating tables for creating concrete countertops, there are several tips to keep in mind to ensure optimal results. First, make sure to properly prepare the molds and concrete mixture before pouring. Clean the molds thoroughly apply a release agent to prevent sticking, and mix the concrete according to manufacturer guidelines to achieve the desired consistency.

Once the molds are filled with concrete, place them on the vibrating table and activate the vibration mechanism. Allow the table to run for a sufficient amount of time to ensure that all air bubbles are removed and the concrete is evenly distributed within the molds. Avoid over-vibrating the concrete, as this can cause segregation and other issues.

After vibrating, allow the concrete to cure according to manufacturer guidelines before demolding and finishing the countertops. Proper curing is essential to ensure the strength and durability of the finished product. Once cured, carefully demold the countertops and inspect them for any imperfections or defects. Sand or grind any rough spots or irregularities, and seal the countertops with a high-quality sealer to protect them from stains, scratches, and moisture.

Common Mistakes to Avoid

Under-Vibrating the Concrete: One common mistake is not vibrating the concrete mixture for a sufficient amount of time, resulting in incomplete removal of air bubbles and a less-than-perfect finish. Make sure to allow an adequate amount of time for vibrating to ensure all air bubbles are eliminated.

Over-Vibrating the Concrete: Conversely, over-vibrating the concrete can also lead to issues such as segregation and uneven distribution of aggregates. Avoid excessive vibration, especially with larger, more powerful vibrating tables, and follow manufacturer guidelines for optimal vibrating times.

Using Incorrect Vibrating Table Settings: Using incorrect settings on the vibrating table, such as excessive vibration intensity or frequency, can lead to undesirable results. Make sure to adjust the settings according to the specific needs of your project and the characteristics of the concrete mixture being used.

Neglecting Proper Mold Preparation: Neglecting to properly prepare the molds before pouring the concrete can result in sticking, uneven surfaces, and difficulty demolding. Make sure to clean the molds thoroughly and apply a release agent to prevent sticking, and inspect the molds for any defects or damage before use.

Can I use a vibrating table for all types of concrete countertop mixes?

Vibrating tables are suitable for use with most types of concrete countertop mixes, including both precast and cast-in-place mixes. However, it’s important to choose a vibrating table with the appropriate intensity and frequency for the specific characteristics of the concrete mixture being used.

How long should I run the vibrating table for?

The duration of vibrating will depend on factors such as the size and thickness of the countertops, the intensity of the vibration, and the characteristics of the concrete mixture. Generally, vibrating should continue until all air bubbles are removed and the concrete is evenly distributed within the molds.

Can I use a handheld vibrating tool instead of a vibrating table?

Handheld vibrating tools can be used for smaller countertop projects or touch-up work on larger countertops, but may not provide the same level of vibration intensity or efficiency as larger vibrating tables. For large-scale production, an industrial-sized vibrating table is recommended.

How do I know if the concrete has been adequately vibrated?

Adequate vibrating is achieved when all air bubbles have risen to the surface and escaped, and the concrete is evenly distributed within the molds. Visual inspection and tapping the sides of the molds can help determine if the concrete has been properly vibrated.

Can I use a vibrating table for other concrete projects besides countertops?

Yes, vibrating tables can be used for a variety of concrete projects besides countertops, including paving stones, tiles, and architectural elements. The key is to choose a vibrating table with the appropriate size and intensity for the specific project at hand.

Tips to Take Your Concrete Countertops to the Next Level

Vibrating Table 2m x 1m

VIBCO – Concrete Countertop Vibrators

Compaction Tables / Vibrating Tables – Houston Vibrator

How to Make an Inexpensive Concrete Vibrating Table GlobMarble

Related articles:

- Outdoor Concrete Countertops

- How To Make Concrete Countertops Smooth

- Rustic Concrete Countertops

- Farmhouse Concrete Countertops

- Concrete Countertops Outdoor Kitchen

- How To Stain Concrete Countertops

- DIY Concrete Countertop Mix

- Concrete Countertops Made Easy

- Concrete Countertop Overlay

- Black Concrete Countertops