A crucial aspect of concrete countertops is the application of a top coat, which plays a pivotal role in enhancing their durability, aesthetics, and overall performance. The top coat serves as a protective layer, shielding the concrete surface from stains, scratches, and other forms of wear and tear. This coating not only contributes to the longevity of the countertop but also provides an opportunity to customize its appearance. Let’s delve into the various aspects of concrete countertop top coats, including their types, application methods, maintenance considerations, and impact on the overall design.

One common type of top coat for concrete countertops is epoxy. Epoxy top coats are known for their exceptional durability and resistance to various forms of damage. These coatings create a hard, glossy surface that not only protects the concrete but also adds a sleek and modern aesthetic to the countertop. Epoxy top coats are particularly popular in contemporary kitchen designs where a seamless, high-gloss finish is desired.

Polyurethane is another popular choice for concrete countertop top coats. This type of coating offers a good balance between durability and flexibility, making it resistant to scratches and impacts while allowing for some movement in the concrete. Polyurethane top coats come in various finishes, from satin to high gloss, providing homeowners with options to match their preferred aesthetic.

When applying a top coat to a concrete countertop, it’s essential to start with a clean and properly cured surface. Any imperfections or contaminants on the concrete can affect the adhesion and appearance of the top coat. The application process typically involves the use of a brush, roller, or sprayer, depending on the type of top coat chosen. Careful and even application is crucial to achieving a uniform finish.

The choice of a top coat can significantly impact the final appearance of a concrete countertop. Some homeowners prefer a matte or satin finish for a more natural and understated look, while others opt for a glossy finish to add a touch of sophistication. The versatility in finishes allows for customization, ensuring that the concrete countertop complements the overall design and style of the kitchen or bathroom.

In addition to enhancing aesthetics, the top coat on a concrete countertop serves as a protective barrier against stains and spills. Concrete is porous, and without proper sealing, it can absorb liquids that may lead to discoloration or damage. The top coat acts as a shield, preventing substances like coffee, wine, or oils from penetrating the surface and making cleanup easier and more effective.

Maintenance of a concrete countertop with a top coat is generally straightforward. Regular cleaning with a mild soap and water solution is usually sufficient to keep the surface looking its best. It’s advisable to avoid harsh or abrasive cleaners that can damage the top coat. Additionally, reapplying a protective top coat periodically, depending on usage and wear, helps maintain the countertop’s resilience over time.

Beyond the practical benefits, the choice of a top coat for a concrete countertop allows for creative expression. Pigments and additives can be introduced to the top coat, enabling homeowners to achieve unique colors, textures, and patterns. This level of customization is particularly appealing for those seeking a one-of-a-kind countertop that reflects their personal style and preferences.

In terms of durability, a well-applied top coat significantly enhances the lifespan of a concrete countertop. It acts as a shield against daily wear and tear, ensuring that the surface remains intact and resistant to scratches, dings, and other forms of damage. This durability is especially crucial in high-traffic areas like kitchens, where countertops are subjected to constant use.

An essential consideration when choosing a top coat for a concrete countertop is its compatibility with the specific needs of the space. For example, in a kitchen where food preparation is frequent, a top coat with antimicrobial properties may be desirable to inhibit the growth of bacteria. Understanding the unique requirements of the environment helps homeowners select a top coat that aligns with both functional and aesthetic considerations.

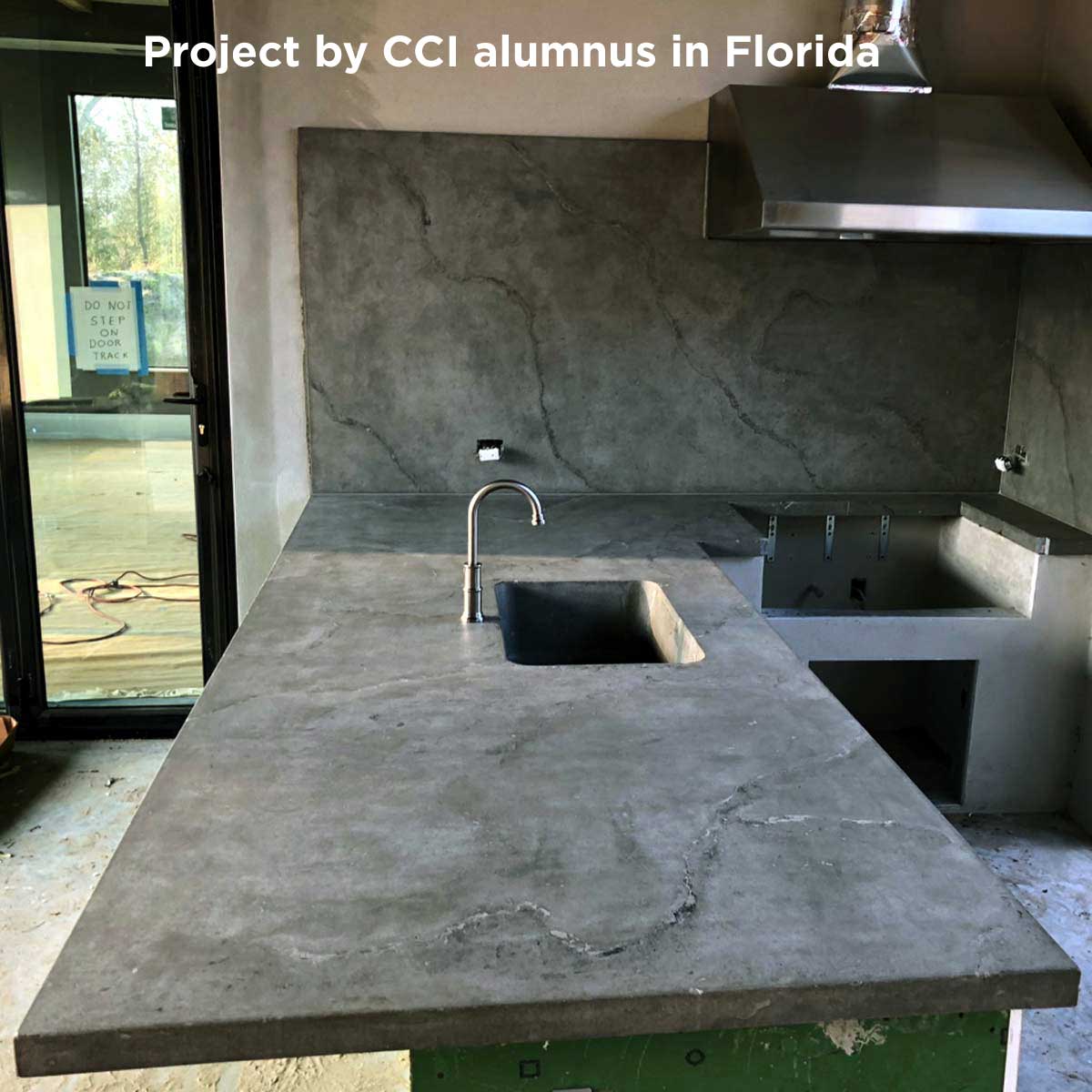

One factor that homeowners often appreciate about concrete countertop top coats is their ability to highlight the natural beauty of the concrete. The top coat enhances the color variations, textures, and subtle imperfections inherent in concrete, creating a visually interesting and dynamic surface. This characteristic is particularly appealing to those who appreciate the raw and organic aesthetics of concrete as a design element.

Sealing a concrete countertop with a top coat also contributes to its resistance to UV radiation. Exposure to sunlight over time can lead to color fading and degradation of the concrete. The top coat acts as a protective layer, preventing UV rays from affecting the appearance of the countertop. This is especially important for outdoor concrete countertops, where exposure to sunlight is unavoidable.

While epoxy and polyurethane are common choices, some homeowners explore alternative top coat options for their concrete countertops. For instance, water-based acrylic sealers offer a low-odor and environmentally friendly option. These sealers protect without the strong fumes associated with some solvent-based coatings, making them a suitable choice for indoor applications.

In the realm of design trends, concrete countertops with a natural, honed finish have gained popularity. This involves applying a top coat with a lower sheen to achieve a matte or satin appearance. This trend aligns with a growing appreciation for more subdued and tactile surfaces, allowing the inherent qualities of the concrete to take center stage without a high-gloss finish.

The choice of a top coat for a concrete countertop is a crucial step in ensuring its longevity, functionality, and aesthetic appeal. Whether opting for epoxy, polyurethane, or alternative sealers, homeowners can tailor the top coat to their specific preferences and the demands of the space. Beyond protection, the top coat allows for creative expression, making concrete countertops a versatile and customizable choice for those seeking a unique and durable surface in their kitchens or bathrooms.

Concrete Countertop DIY – A Beautiful Mess

How to DIY a Concrete Bar Top – In a weekend! – A Life Unfolding

DIY White Concrete Skimcoat Countertop u2014 Liz Morrow

DIY Feather Finish Concrete Countertops – Blessu0027er House

DIY Concrete Over Laminate Countertops Using Feather Finish

Related articles:

- Cost Of Concrete Countertop Per Square Foot

- Vibrating Table For Concrete Countertops

- Concrete Countertop Coatings

- How To Make Concrete Countertops For Outdoor Kitchens

- Concrete Countertop Edge Profile Forms

- How To Build An Outdoor Concrete Countertop

- Glass In Concrete Countertops

- Concrete Countertops That Look Like Marble

- Concrete Countertops For Kitchens

- Concrete Countertop For Outdoor Kitchen