Concrete countertops have gained popularity for their durability and modern aesthetic, but one key to their longevity and strength is proper reinforcement. Reinforcing concrete countertops involves embedding materials like rebar, wire mesh, or fiberglass fibers within the concrete to enhance its structural integrity. This process prevents cracking, supports weight distribution, and extends the lifespan of the countertop.

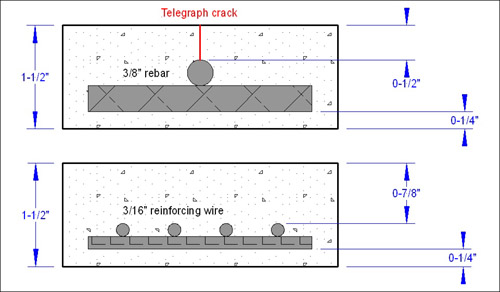

The first step in reinforcing a concrete countertop is to choose the right reinforcement materials. Steel rebar is a common choice, offering excellent tensile strength. It is typically used in larger countertops or those with overhangs where additional support is needed. Wire mesh is another option, providing a grid that helps distribute stress evenly across the surface. Fiberglass fibers can be mixed directly into the concrete, offering a less visible form of reinforcement that increases the material’s overall toughness and resistance to cracking.

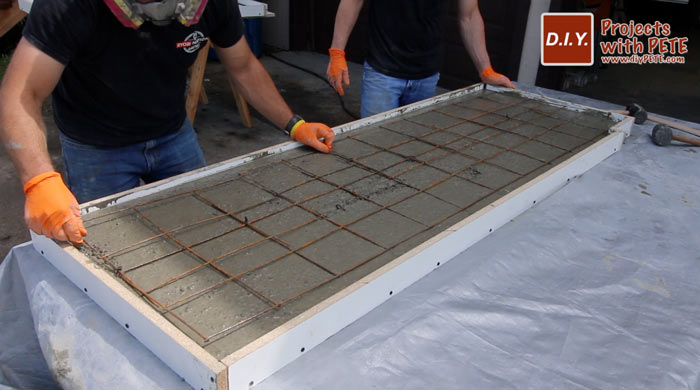

When using steel rebar or wire mesh, it’s important to properly place these materials within the concrete form. The rebar should be spaced according to the size and shape of the countertop, often in a grid pattern, and positioned to sit within the lower third of the slab for optimal tensile reinforcement. The wire mesh should be cut to fit the form and placed in the center of the slab. Both rebar and mesh need to be supported by chairs or other spacers to ensure they remain in place while the concrete is poured and cures.

Fiberglass fibers are added to the concrete mix before pouring. These fibers distribute throughout the concrete, providing reinforcement that helps control shrinkage and cracking. They are particularly useful in thin countertops where traditional reinforcement methods might not be feasible. The amount of fiber added depends on the manufacturer’s recommendations and the specific needs of the project.

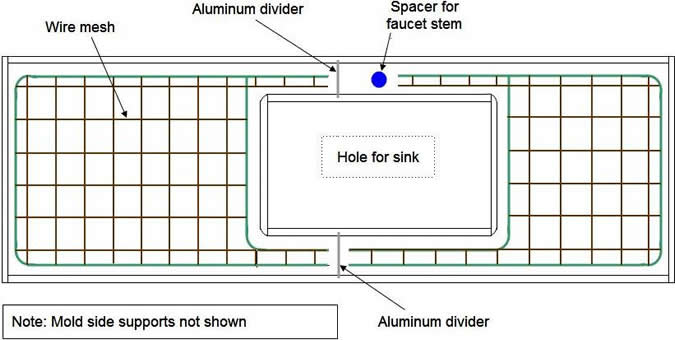

Preparing the concrete form is another crucial step in the reinforcement process. The form must be constructed to the exact dimensions of the countertop, ensuring a tight seal to prevent leaks. It should be sturdy enough to withstand the weight of the concrete and the pressure during pouring. Before adding reinforcement materials, apply a release agent to the form to facilitate easy removal once the concrete has cured.

Pouring the concrete requires careful attention to ensure even distribution and proper encapsulation of the reinforcement materials. Start by pouring a base layer of concrete to cover the bottom of the form. If using rebar or wire mesh, place these materials onto the base layer and then continue pouring the concrete until the form is filled. Vibrating the form or using a concrete vibrator helps eliminate air pockets and ensures the concrete settles evenly around the reinforcement.

After pouring, the concrete must cure properly to develop its full strength. This process typically takes about 28 days, during which the countertop should be kept moist to prevent rapid drying and cracking. Covering the countertop with plastic sheeting or using a curing compound helps maintain the necessary moisture levels. During this time, avoid placing any heavy objects on the countertop to prevent stress before it has fully cured.

Sealing the countertop is essential to protect the concrete from stains, moisture, and daily wear. A high-quality sealer will penetrate the surface and create a durable barrier. The type of sealer used depends on the desired finish—some sealers enhance the natural color of the concrete, while others provide a glossy or matte finish. It’s important to apply the sealer according to the manufacturer’s instructions and allow it to cure fully before using the countertop.

Maintenance of a concrete countertop involves regular cleaning and periodic resealing. Use a mild detergent and water for daily cleaning, and avoid harsh chemicals that can damage the sealer. Depending on usage, resealing may be necessary every one to three years to maintain the protective barrier. Resealing involves cleaning the countertop thoroughly, applying a new coat of sealer, and allowing it to cure completely.

Design considerations also play a role in the reinforcement of concrete countertops. For instance, countertops with integrated sinks, curves, or intricate shapes may require additional reinforcement to support these features. Planning for these design elements during the reinforcement stage ensures that the finished countertop can handle the unique stresses and loads associated with its design.

Properly reinforced concrete countertops can accommodate various custom features such as embedded items, inlays, or decorative finishes. These elements can add visual interest and personalization to the countertop. However, incorporating such features requires careful planning to ensure that the reinforcement does not interfere with the placement of these items and that the structural integrity is maintained.

Environmental factors such as temperature and humidity can affect the curing and performance of concrete countertops. In colder climates, it may be necessary to protect the countertop from freezing during the curing process, while in hot and dry conditions, extra measures to retain moisture might be required. Understanding and planning for these environmental variables helps ensure a successful project.

For countertops with overhangs or cantilevers, additional reinforcement is essential. These areas are prone to stress and need support to prevent sagging or cracking. Using thicker rebar or doubling up on wire mesh in these areas provides the necessary strength. Additionally, installing hidden brackets or supports can provide extra stability without detracting from the aesthetic appeal.

When integrating appliances or fixtures, ensure that cutouts for sinks, stoves, or faucets are properly reinforced to prevent weak points. This involves adding extra rebar or mesh around the cutout areas and ensuring the edges are smooth to prevent stress concentration. Proper reinforcement around these areas is critical to avoid cracks that can develop from daily use and the weight of the fixtures.

Overall, the success of a concrete countertop project heavily depends on meticulous planning and execution of the reinforcement process. Each step, from choosing the right materials to proper placement and curing, contributes to the durability and aesthetic quality of the finished product. Reinforcing a concrete countertop may require additional effort and cost, but the investment pays off in a long-lasting, beautiful kitchen feature that can withstand the rigors of daily use.

Common Mistakes to Avoid

Inadequate Reinforcement Placement: Placing rebar or mesh incorrectly can lead to insufficient support and potential cracking. Ensure that reinforcement materials are properly positioned within the concrete form and supported by chairs or spacers.

Using Incorrect Materials: Not all reinforcement materials are suitable for every project. Choose the right type of reinforcement (rebar, mesh, fibers) based on the countertop’s size, shape, and load requirements.

Improper Concrete Mixing: A poor mix can result in weak concrete that is prone to cracking. Follow the mix design specifications accurately, ensuring the right proportions of cement, aggregates, and water.

Skipping the Curing Process: Allowing the concrete to dry too quickly can cause cracks and reduce strength. Proper curing, including maintaining moisture and temperature, is essential for achieving full strength.

Neglecting Environmental Factors: Ignoring temperature and humidity conditions during curing can compromise the concrete. Plan for environmental conditions to ensure optimal curing and long-term durability.

Overlooking Sealing and Maintenance: Failing to seal the countertop properly or neglecting regular maintenance can lead to staining and surface damage. Apply a high-quality sealer and maintain it according to the manufacturer’s recommendations.

Not Accounting for Design Features: Integrated sinks, curves, or overhangs require additional reinforcement. Plan for these features during the reinforcement stage to ensure the countertop can handle the associated stresses.

What materials are best for reinforcing a concrete countertop?

The best materials for reinforcing a concrete countertop include steel rebar, wire mesh, and fiberglass fibers. Steel rebar provides excellent tensile strength and is ideal for larger countertops or those with overhangs. Wire mesh offers a grid that distributes stress evenly, while fiberglass fibers mixed into the concrete enhance overall toughness and resistance to cracking. The choice of reinforcement material depends on the specific requirements of the project.

How do I properly place reinforcement in a concrete countertop?

Proper placement of reinforcement involves positioning materials like rebar or wire mesh within the lower third of the concrete slab for optimal tensile reinforcement. The rebar should be spaced in a grid pattern and supported by chairs or spacers to ensure it stays in place. Wire mesh should be cut to fit the form and placed in the center of the slab. Both types of reinforcement must be adequately supported to prevent shifting during the concrete pour and curing process.

What is the curing process for a reinforced concrete countertop?

The curing process for a reinforced concrete countertop involves keeping the concrete moist for about 28 days to develop full strength. This can be achieved by covering the countertop with plastic sheeting or using a curing compound to maintain moisture levels. Avoid placing heavy objects on the countertop during curing to prevent stress before the concrete fully hardens. Proper curing is crucial to prevent rapid drying and cracking.

How often should I seal and maintain my concrete countertop?

Concrete countertops should be sealed initially after curing and then resealed periodically to maintain their protective barrier. The frequency of resealing depends on the usage and the type of sealer used, typically every one to three years. Regular cleaning with a mild detergent and water is essential, avoiding harsh chemicals that can damage the sealer. Resealing involves thoroughly cleaning the countertop, applying a new coat of sealer, and allowing it to cure completely.

Can I customize my reinforced concrete countertop with inlays or decorative features?

Yes, reinforced concrete countertops can be customized with inlays, embedded items, and decorative finishes. These features require careful planning during the reinforcement stage to ensure they do not interfere with the structural integrity. Properly reinforcing areas around inlays or cutouts and ensuring the reinforcement materials do not obstruct the placement of decorative elements is essential. Custom features can add visual interest and personalization to the countertop while maintaining durability.

What is the Right Amount of Reinforcement for a Concrete

A Carpenters First Time Building Concrete Countertops Pro Remodeler

Rebar and wire mesh reinforcement for your concrete countertop

How to Make Concrete Counters for an Outdoor Kitchen – DIY Pete

Related articles:

- Outdoor Concrete Countertops

- How To Make Concrete Countertops Smooth

- Rustic Concrete Countertops

- Farmhouse Concrete Countertops

- Concrete Countertops Outdoor Kitchen

- How To Stain Concrete Countertops

- DIY Concrete Countertop Mix

- Concrete Countertops Made Easy

- Concrete Countertop Overlay

- Black Concrete Countertops