Edge forms for concrete countertops play a crucial role in determining the aesthetic appeal and functionality of the final product. These forms are essentially molds that shape the edges of the concrete during the casting process, giving countertops their distinctive look and feel. Choosing the right edge form is essential for achieving the desired design, strength, and durability of the countertop. Let’s delve into the intricacies of edge forms for concrete countertops:

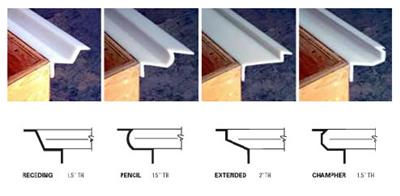

Types of Edge Forms: Edge forms come in various shapes and sizes, each offering a unique appearance to the countertop. Some common types include straight, bullnose, ogee, beveled, and chiseled edges. Straight edges provide a clean and modern look, while bullnose edges offer a softer, rounded profile. Ogee edges add elegance with their intricate curves, while beveled edges create a subtle angled effect. Chiseled edges mimic the appearance of natural stone, adding rustic charm to the countertop.

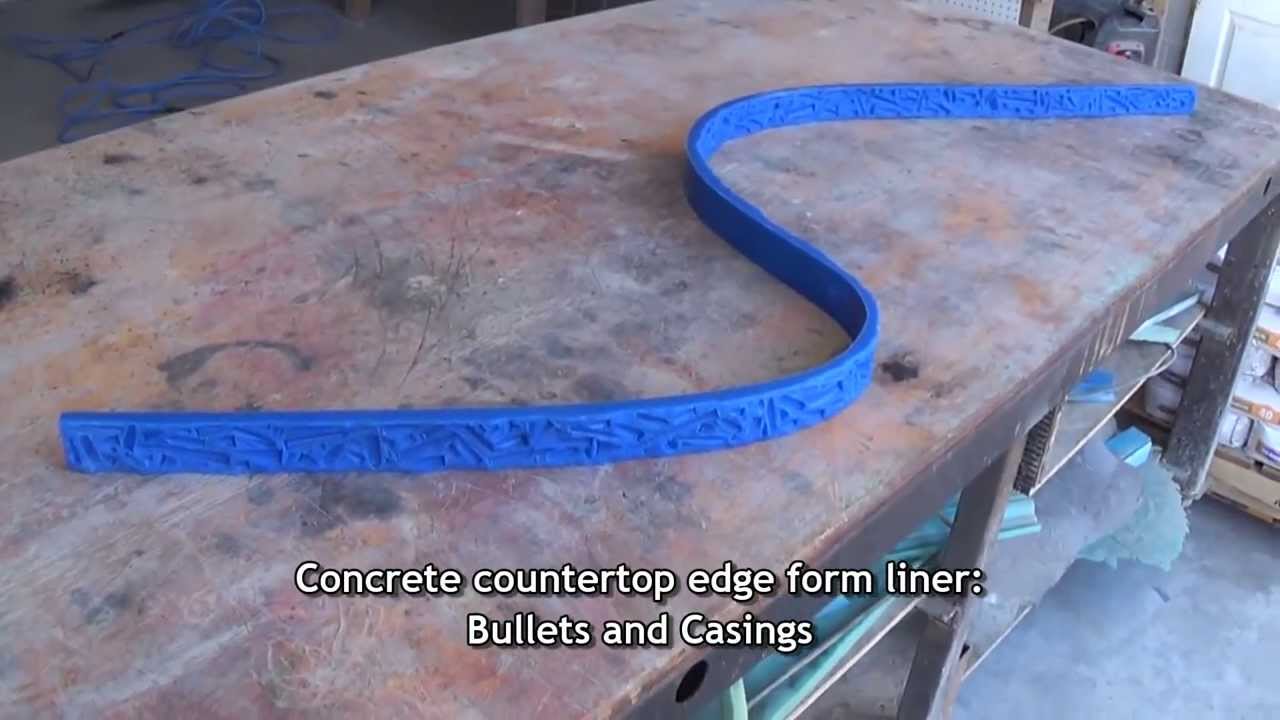

Materials Used: Edge forms are typically made from materials such as plastic, rubber, wood, or metal. Plastic forms are lightweight and easy to work with, making them suitable for DIY projects. Rubber forms are flexible and can create intricate designs, but may require additional support during casting. Wood forms offer a classic look and can be easily customized, but may warp or deteriorate over time. Metal forms are durable and can withstand repeated use, making them ideal for professional applications.

Installation Process: Installing edge forms involves attaching them securely to the mold before pouring the concrete. This ensures that the edges maintain their shape and definition during the casting process. Depending on the type of form used, installation methods may vary. Plastic and rubber forms can be secured with adhesive or clamps, while wood and metal forms may require screws or nails for stability.

Releasing Agents: To prevent the concrete from sticking to the edge forms, it’s essential to apply a releasing agent before pouring. Common releasing agents include vegetable oil, mineral oil, or specialized form release agents. These agents create a barrier between the concrete and the form, allowing for easy removal once the countertop has cured.

Finishing Techniques: After the concrete has been poured and cured, the edge forms are removed to reveal the finished edges of the countertop. Depending on the desired look, various finishing techniques can be applied. This may include sanding, grinding, polishing, or applying a decorative overlay. Finishing the edges not only enhances the appearance of the countertop but also helps to smooth out any imperfections or rough edges.

Sealing and Protection: Once the countertop is complete, it’s essential to seal the surface to protect it from stains, water damage, and other environmental factors. A high-quality concrete sealer should be applied according to the manufacturer’s instructions. This not only enhances the durability of the countertop but also brings out the natural beauty of the concrete.

Customization Options: Edge forms offer endless possibilities for customization, allowing homeowners and designers to create unique and personalized countertops. From choosing the shape and profile of the edges to adding decorative inserts or embedded objects, the options are virtually limitless. This allows for creative expression and ensures that each countertop is one-of-a-kind.

Durability and Maintenance: Concrete countertops are known for their durability and longevity when properly cared for. However, it’s essential to follow proper maintenance practices to ensure their longevity. This includes avoiding abrasive cleaners, acidic substances, and excessive heat exposure. Regular cleaning with mild soap and water, along with periodic resealing, will help preserve the beauty and integrity of the countertop.

Cost Considerations: The cost of edge forms for concrete countertops can vary depending on factors such as material, complexity of design, and customization options. Plastic and rubber forms are generally more affordable and readily available, making them suitable for budget-conscious projects. Wood and metal forms may be more expensive upfront but offer durability and versatility in design.

Environmental Impact: Concrete countertops are considered a sustainable option compared to traditional materials like granite or marble. Concrete is locally sourced and can be made with recycled materials, reducing the carbon footprint associated with countertop production. Additionally, concrete countertops can last for decades with proper maintenance, further minimizing environmental impact.

Common Mistakes to Avoid:

Poor Form Alignment: Improper alignment of edge forms can result in uneven edges or misshapen countertops. Take the time to ensure that the forms are level and securely fastened to the mold before pouring the concrete.

Insufficient Releasing Agent: Failing to apply enough releasing agent can cause the concrete to stick to the edge forms, making removal difficult and potentially damaging the countertop edges. Be generous with the releasing agent to facilitate easy removal.

Overworking the Concrete: Excessive troweling or manipulation of the concrete can lead to air bubbles, voids, or surface imperfections. Work the concrete just enough to achieve the desired finish, avoiding overworking that can compromise the structural integrity of the countertop.

Skipping Sealing and Protection: Neglecting to seal the countertop after installation leaves it vulnerable to stains, moisture damage, and wear over time. Invest in a high-quality sealer and follow proper application techniques to ensure long-term durability.

Ignoring Maintenance: Failing to maintain the countertop properly can diminish its appearance and lifespan. Regular cleaning, sealing, and avoiding harsh chemicals or abrasive materials are essential for preserving the beauty and integrity of concrete countertops.

Can I install edge forms myself?

Yes, edge forms can be installed by DIY enthusiasts with some basic knowledge and skills. However, it’s essential to follow proper installation techniques and use the right tools and materials to ensure a successful outcome.

How long does it take for concrete countertops to cure?

The curing time for concrete countertops can vary depending on factors such as temperature, humidity, and the type of concrete used. In general, countertops may take anywhere from a few days to a few weeks to fully cure and reach their maximum strength.

Can I change the color of my concrete countertop after it’s been installed?

Yes, concrete countertops can be stained or dyed to change their color after installation. There are various staining and coloring techniques available to achieve the desired look, allowing for customization even after the countertop is in place.

Are concrete countertops heat resistant?

Concrete countertops are generally heat resistant but may be susceptible to damage from extreme temperatures or prolonged exposure to heat. It’s advisable to use trivets or hot pads to protect the surface from direct contact with hot cookware or appliances.

How long do concrete countertops last?

With proper care and maintenance, concrete countertops can last for decades. Regular cleaning, sealing, and avoiding abrasive materials will help preserve the appearance and integrity of the countertop for years to come.

Edge Detail for Concrete Countertops

Rafael Oak Leaf (2″ x 8u0027)

Concrete Countertop Edge Form – Chiseled Slate

DIY Concrete Countertop Desk, Custom Edge Effects

Bullet Edge Concrete Countertop Form Liner

Related articles:

- How To Stain Concrete Countertops

- DIY Concrete Countertop Mix

- Concrete Countertops Made Easy

- Concrete Countertop Overlay

- Black Concrete Countertops

- Marble Look Concrete Countertops

- Light Grey Concrete Countertops

- Concrete Countertop Design Ideas

- Light Colored Concrete Countertops

- Epoxy On Concrete Countertop