Epoxy bathroom countertops are a modern and stylish option for homeowners looking to upgrade their bathroom surfaces. Epoxy is a versatile material known for its durability, high-gloss finish, and ability to mimic the look of more expensive materials like marble and granite. Applying epoxy to bathroom countertops involves coating the existing surface with a resin-based compound that hardens to form a smooth, waterproof, and resilient finish. This process can transform old, worn countertops into sleek, contemporary surfaces that enhance the overall aesthetic of the bathroom.

The process of creating epoxy bathroom countertops starts with thorough preparation of the existing countertop. This involves cleaning the surface to remove any dirt, grease, or soap residue, as any contaminants can interfere with the adhesion of the epoxy. After cleaning, the countertop needs to be sanded to create a rough texture that helps the epoxy bond effectively. Use medium-grit sandpaper and sand the entire surface evenly. After sanding, wipe the countertop with a damp cloth to remove any dust and allow it to dry completely.

Next, any imperfections in the countertop should be repaired. Cracks, chips, or holes can be filled with a suitable filler, such as a two-part epoxy putty. Once the filler has cured, sand it smooth to ensure the countertop surface is even. If there are any large areas of damage or significant wear, it may be necessary to apply a primer to the countertop to create a uniform base for the epoxy. The primer also helps to enhance adhesion and improve the durability of the epoxy finish.

The actual application of epoxy involves mixing the resin and hardener components according to the manufacturer’s instructions. Epoxy resin is a two-part system that, when mixed, undergoes a chemical reaction that causes it to harden. It’s important to mix the components thoroughly to ensure a consistent cure. Once mixed, the epoxy should be poured onto the countertop and spread evenly using a notched trowel or a roller. The notches help to distribute the epoxy uniformly, and a roller can smooth out any lines or bubbles.

One of the key advantages of epoxy countertops is their seamless, high-gloss finish. As the epoxy cures, it levels itself to form a smooth, glass-like surface. This finish not only looks luxurious but also provides excellent protection against moisture and stains. Epoxy is naturally water-resistant, making it an ideal choice for bathroom environments where water exposure is constant. The seamless nature of epoxy also means there are no joints or seams where water can seep through, reducing the risk of water damage to the underlying countertop.

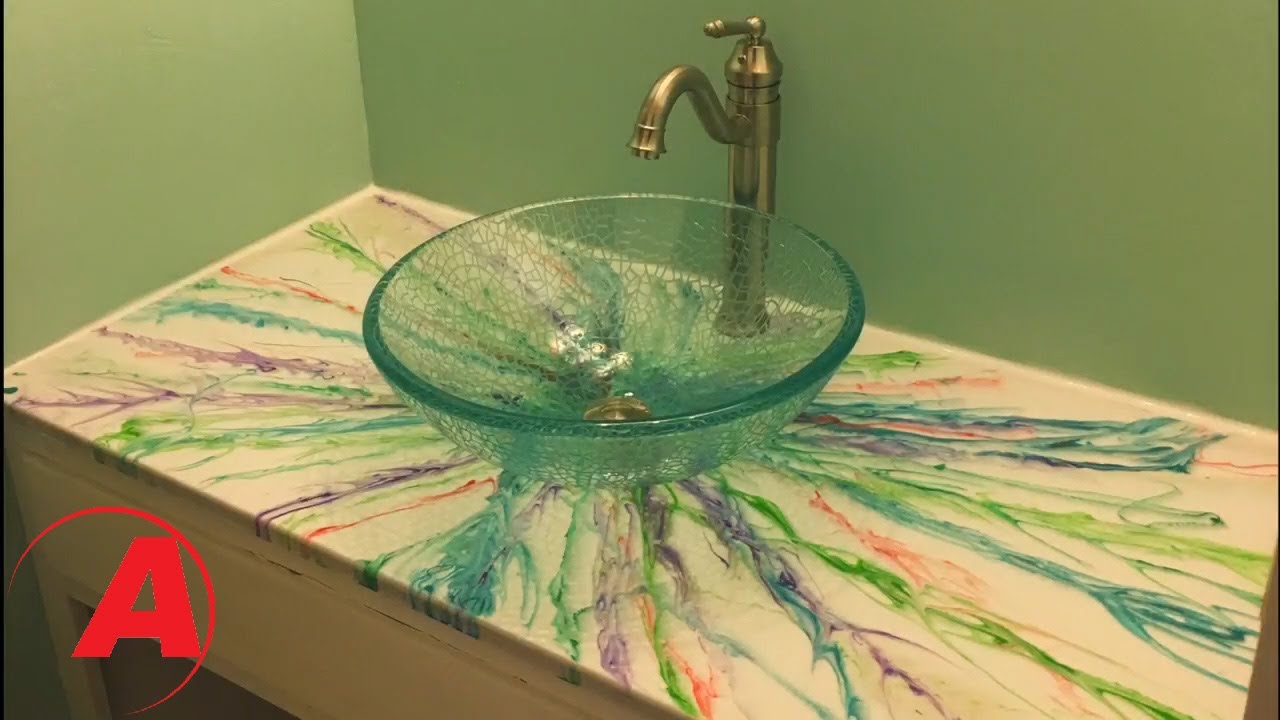

Epoxy can be tinted or combined with various additives to create a wide range of colors and effects. Metallic pigments, for example, can be mixed into the epoxy to create a shimmering, marble-like appearance. Other additives, such as colored chips or flakes, can be sprinkled onto the wet epoxy to create a textured, granite-like finish. The versatility of epoxy allows for endless customization options, enabling homeowners to achieve a unique and personalized look for their bathroom countertops.

The curing process for epoxy countertops is critical for achieving a durable finish. Depending on the specific product and environmental conditions, epoxy can take several hours to several days to fully cure. During this time, it’s important to protect the countertop from dust, debris, and any contact that could mar the surface. Proper ventilation is also essential to ensure that fumes from the curing epoxy are safely dispersed. Once fully cured, the epoxy surface will be hard, resilient, and ready for use.

Maintenance of epoxy bathroom countertops is relatively simple. The smooth, non-porous surface makes cleaning easy, as dirt and grime can be wiped away with a damp cloth and a mild detergent. Unlike porous materials like natural stone, epoxy does not require sealing to maintain its water resistance. However, it’s important to avoid using abrasive cleaners or scrubbers that could scratch the glossy finish. Regular cleaning and gentle handling will keep the countertop looking pristine for years to come.

Epoxy is also known for its resistance to common bathroom chemicals and cosmetics. Unlike some natural stones that can be damaged by acidic or alkaline substances, epoxy can withstand exposure to a wide range of products without staining or etching. This makes it an ideal surface for bathroom vanities where soaps, lotions, and other toiletries are frequently used. The durability of epoxy ensures that it maintains its appearance and performance despite the daily wear and tear of a busy bathroom.

In terms of cost, epoxy countertops are generally more affordable than natural stone options like granite or marble. The materials themselves are relatively inexpensive, and the application process can often be completed as a DIY project, further reducing costs. While professional installation is available and recommended for those seeking a flawless finish, many homeowners find that they can achieve excellent results on their own with careful preparation and attention to detail.

Another advantage of epoxy countertops is their environmental impact. Epoxy resin can be used to refurbish existing countertops, reducing the need for new materials and the associated environmental costs of mining and transportation. Additionally, epoxy’s durability means that it does not need to be replaced as frequently as other countertop materials, reducing waste over time. Some manufacturers also offer eco-friendly epoxy products made from renewable or recycled materials, further enhancing the sustainability of this option.

One of the challenges of working with epoxy is the potential for air bubbles to become trapped in the resin during mixing or application. These bubbles can mar the smooth finish of the countertop if not addressed. To prevent bubbles, it’s important to mix the epoxy slowly and thoroughly, avoiding vigorous stirring that can introduce air. During application, a heat gun or torch can be used to gently pass over the surface and release any trapped air bubbles, ensuring a flawless finish.

Epoxy countertops are also highly resistant to heat, which is a valuable property in bathroom environments where hot tools like hair dryers and curling irons are used. While it’s still advisable to use heat-resistant mats or trivets to protect the surface, epoxy’s heat resistance means it can withstand occasional exposure to high temperatures without sustaining damage. This adds to the practicality and longevity of epoxy as a countertop material.

For those interested in DIY projects, epoxy countertop kits are available that include everything needed to complete the refinishing process. These kits typically include the resin and hardener, color pigments, additives for texture or effects, and detailed instructions. While working with epoxy requires care and precision, the availability of these kits makes it accessible for homeowners to achieve professional-looking results on their own.

Epoxy bathroom countertops offer a combination of beauty, durability, and versatility that makes them an excellent choice for modern bathrooms. The seamless, high-gloss finish provides a luxurious appearance while protecting against water damage, stains, and daily wear. With a wide range of colors and effects available, epoxy can be customized to suit any design preference, offering an affordable and sustainable alternative to more traditional countertop materials.

Common Mistakes to Avoid:

Skipping Surface Preparation: Properly cleaning and sanding the countertop before applying epoxy is crucial. Failure to do so can result in poor adhesion and an uneven finish.

Incorrect Mixing: Not thoroughly mixing the resin and hardener can lead to incomplete curing. Follow the manufacturer’s instructions precisely for mixing ratios and procedures.

Applying Too Thickly: Pouring too much epoxy at once can cause it to run or sag. Apply in thin, even layers to achieve a smooth finish.

Not Controlling Temperature: Epoxy curing can be affected by temperature. Work in a controlled environment to ensure the best results.

Ignoring Air Bubbles: Trapped air bubbles can mar the finish. Use a heat gun or torch to release bubbles as the epoxy cures.

Using Abrasive Cleaners: After curing, avoid abrasive cleaners that can scratch the surface. Use mild detergents and soft cloths for cleaning.

Rushing the Curing Process: Allow adequate curing time for the epoxy to harden completely. Premature use can damage the finish.

Neglecting Ventilation: Proper ventilation is important to disperse fumes during the application and curing process. Ensure good airflow in the workspace.

Improper Protection During Curing: Protect the curing epoxy from dust, debris, and contact to prevent imperfections in the finish.

Overlooking Edges and Corners: Pay attention to edges and corners to ensure they are evenly coated and free of drips.

How long does it take for epoxy to cure on a bathroom countertop?

Epoxy typically takes several hours to become tack-free and several days to fully cure, depending on the product and environmental conditions. Most epoxies will be touch-dry within 24 hours, but it’s advisable to wait at least 72 hours before using the countertop to ensure it has fully hardened. Full curing can take up to a week, during which time the epoxy continues to gain strength and durability. Proper curing is essential to achieve a hard, resilient finish that can withstand daily use.

Can I apply epoxy over any type of existing countertop?

Epoxy can be applied over a variety of countertop materials, including laminate, wood, concrete, and tile. The key to successful application is proper surface preparation. The existing countertop must be thoroughly cleaned, sanded, and repaired to create a smooth, even base for the epoxy. Any imperfections or damage in the underlying surface can affect the final finish. It’s important to follow the manufacturer’s instructions for surface preparation to ensure optimal adhesion and durability.

How durable are epoxy bathroom countertops compared to other materials?

Epoxy countertops are highly durable and resistant to water, stains, and heat, making them an excellent choice for bathroom environments. While they may not be as hard as natural stone, they provide a robust and resilient surface that can withstand daily wear and tear. Epoxy’s seamless finish also means there are no joints or seams where water can seep through, reducing the risk of water damage. With proper care and maintenance, epoxy countertops can last many years, making them a cost-effective and attractive option.

What maintenance is required for epoxy countertops?

Maintaining epoxy countertops is relatively simple. The smooth, non-porous surface can be easily cleaned with a damp cloth and a mild detergent. Avoid using abrasive cleaners or scrubbers that can scratch the glossy finish. Regular cleaning will help maintain the countertop’s appearance and prevent the buildup of soap scum or other residues. While epoxy is heat-resistant, it’s still advisable to use heat-resistant mats or trivets to protect the surface from hot tools. Proper care and gentle handling will ensure the longevity of the epoxy finish.

Can epoxy be repaired if it gets damaged?

Minor scratches or chips in an epoxy countertop can often be repaired using a touch-up kit or additional epoxy. For small repairs, clean the area thoroughly and apply a thin layer of mixed epoxy to the damaged spot, smoothing it out with a putty knife or similar tool. Allow the epoxy to cure fully before using the countertop. For larger repairs or extensive damage, it may be necessary to sand down the affected area and reapply a fresh coat of epoxy. In some cases, professional repair services can provide a seamless fix.

Is epoxy safe for use in bathrooms?

Epoxy is safe for use in bathrooms when applied and cured correctly. Once fully cured, epoxy forms a hard, non-toxic surface that is resistant to water and stains. However, the application process involves working with chemicals that can emit fumes, so proper ventilation and protective equipment, such as gloves and masks, are important during installation. Follow the manufacturer’s safety guidelines and ensure adequate airflow in the workspace to minimize exposure to fumes. Once cured, the epoxy surface is safe and suitable for bathroom use.

CounterTop Epoxy (XC-230) – USANNEX

Update Your Outdated Countertops for LESS than $4

Related articles: