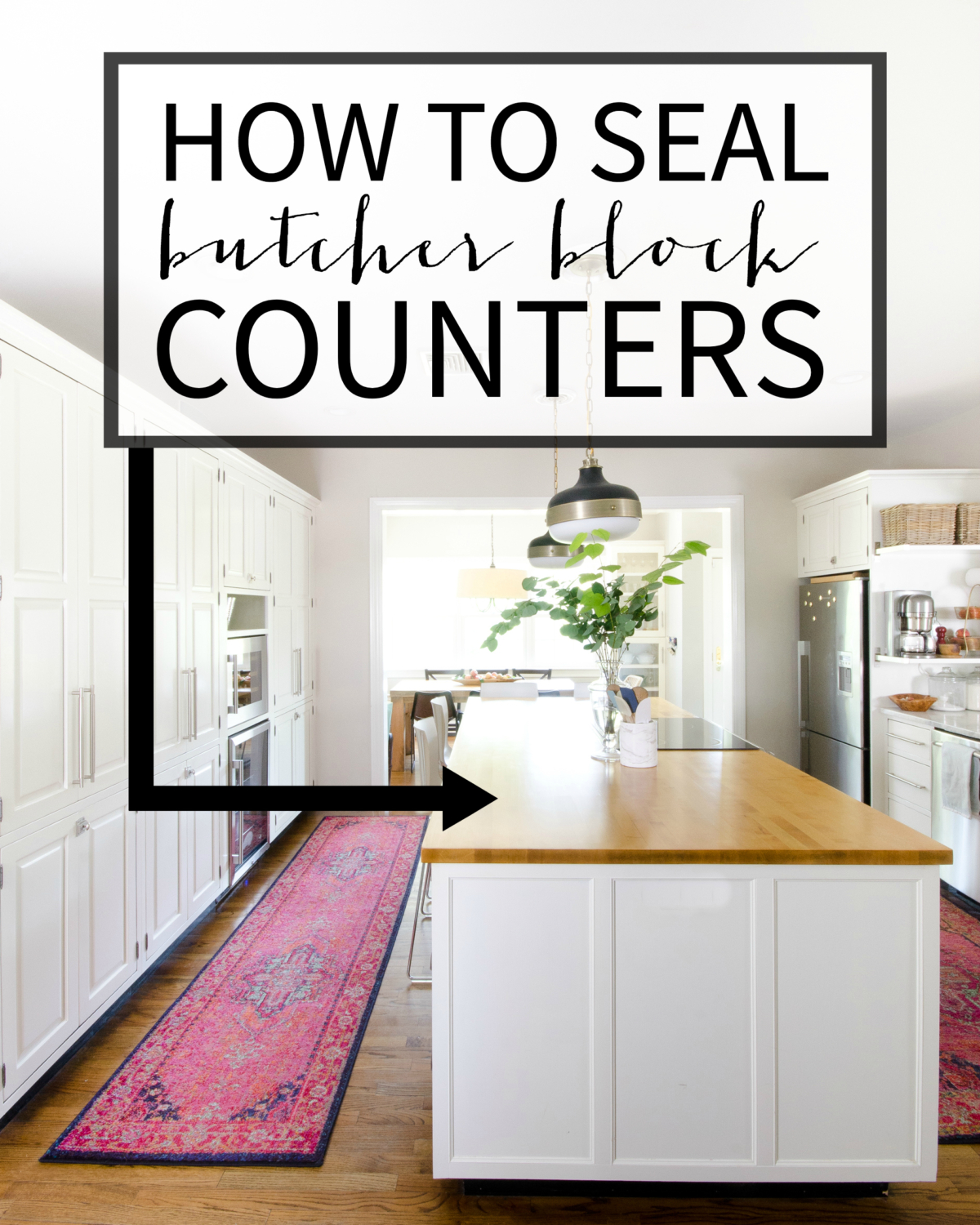

Sealing butcher block countertops is one of the most crucial steps in ensuring their durability and longevity. The natural beauty of wood brings warmth and texture to a kitchen, but without the proper sealing process, it can easily be damaged by moisture, stains, and everyday wear. Butcher block countertops have become increasingly popular for their rustic charm and versatility, but to maintain their aesthetic appeal and functionality, sealing is essential. When done correctly, the sealing process not only protects the wood from damage but also enhances its natural grain and color, allowing it to serve as both a practical work surface and a design focal point in the kitchen.

The sealing process begins with the selection of the right type of sealer. There are two main categories to consider: oil-based finishes and varnish-based finishes. Oil-based finishes, such as mineral oil or tung oil, penetrate the wood and nourish it from within. They are food-safe and ideal for surfaces where food preparation will take place. On the other hand, varnish-based finishes, like polyurethane, form a hard, protective coating on the surface of the wood, providing excellent resistance to water and stains. However, they are not always food-safe, making them better suited for countertops that will be used primarily for aesthetic purposes rather than heavy food prep. Choosing the right type of finish depends on how you plan to use your countertops.

Before applying any sealer, it is important to prepare the surface of the butcher block properly. This involves sanding the wood to remove any imperfections, scratches, or rough patches. Sanding also helps open up the wood’s pores, making it more receptive to the sealer. Start with coarse-grit sandpaper and gradually work your way to finer grits to achieve a smooth finish. After sanding, ensure that the countertop is completely clean and free from dust, as any residue left behind can affect the appearance and effectiveness of the sealer. A thorough cleaning with a damp cloth followed by a dry wipe will prepare the surface for the next steps.

Applying the sealer is a meticulous process that requires attention to detail. If using an oil-based finish, the application is relatively simple. You can use a clean cloth to rub the oil into the wood, making sure to follow the grain. Be generous with the oil, allowing the wood to absorb as much as it can. After the first application, let it sit for about 15-20 minutes before wiping off any excess oil. This step may need to be repeated several times, especially if the wood is new and has not been previously sealed. The goal is to saturate the wood with oil so that it is well-protected and can withstand moisture and use over time.

For varnish-based finishes, the application process is slightly different. Using a brush or a foam applicator, apply an even coat of the varnish, making sure to avoid drips or pooling. It is important to work in thin, even layers, as thicker coats can result in a cloudy or uneven finish. Allow each coat to dry thoroughly before applying the next one, usually 24 hours between coats. Depending on the type of varnish, multiple coats may be required to achieve the desired level of protection. Sand lightly between coats with fine-grit sandpaper to ensure a smooth, professional-looking finish. Once the final coat is applied, allow the countertop to cure for several days before using it.

Maintenance is key to ensuring the longevity of a butcher block countertop. Even with proper sealing, wood is still a natural material that reacts to its environment. Regular reapplication of the oil or finish is necessary to keep the wood protected. For oil-based finishes, reapplication may be needed every few months, especially in high-use areas. Simply clean the surface, sand lightly if necessary, and apply a fresh coat of oil. For varnish-based finishes, reapplication may be less frequent, but over time, the protective layer can wear down, especially in areas exposed to water and food prep. Touch-ups may be needed every few years to maintain the countertop’s appearance and protective qualities.

One of the benefits of sealing butcher block countertops is the added protection against water damage. Wood is naturally porous, which means that it can absorb moisture easily if left unsealed. Water damage can lead to warping, swelling, and even mold growth in extreme cases. A well-sealed countertop will repel water and prevent it from soaking into the wood, protecting the integrity of the material. However, even with sealing, it’s important to clean up spills promptly and avoid prolonged exposure to water, particularly around sinks and other wet areas.

In addition to water protection, sealing helps guard against stains. Butcher block countertops are particularly vulnerable to stains from food, oils, and other kitchen substances. Once the wood is sealed, it becomes much easier to clean, and stains are less likely to penetrate the surface. This is especially important in kitchens where food preparation is a daily task. Sealed countertops are more resistant to acidic substances like lemon juice or vinegar, which can cause discoloration on unsealed wood. Regular cleaning with mild soap and water, followed by drying, will help preserve the countertop’s finish.

Aesthetics also play a significant role in the decision to seal butcher block countertops. The sealer enhances the natural beauty of the wood, bringing out its grain and color. Whether you prefer a glossy, matte, or satin finish, the sealer can create the look you desire while providing the protection the countertop needs. Some people opt for tinted oils or stains to change the color of the wood, while others prefer a clear finish that highlights the natural tones. Whatever your preference, the sealing process allows you to customize the look of your countertop while ensuring it remains functional and durable.

While sealing is essential, it is not a one-time process. Over time, the finish will wear down, especially in areas that see heavy use. This is why regular maintenance is so important. By keeping an eye on the condition of the sealer and reapplying it as needed, you can extend the life of your butcher block countertops significantly. Neglecting to maintain the finish can result in damage that is difficult or impossible to repair, such as deep stains, water damage, or cracks. By investing a little time in maintenance, you can keep your countertops looking and performing their best for many years.

Some homeowners may be tempted to skip the sealing process altogether, especially if they love the natural look of unfinished wood. However, this can be a costly mistake. Unsealed butcher block countertops are highly susceptible to damage from water, food stains, and general wear and tear. In a busy kitchen environment, it’s only a matter of time before the wood becomes stained, warped, or even begins to crack. Sealing not only protects the wood from damage but also makes it easier to clean and maintain, preserving its beauty and functionality for years to come.

It’s also important to use the right products for cleaning and maintaining your sealed butcher block countertops. Harsh chemicals can damage the finish and even strip away the protective layer, leaving the wood vulnerable. Stick to mild, natural cleaners, such as diluted vinegar or gentle dish soap, to clean your countertops. Always dry the surface thoroughly after cleaning to prevent water from sitting on the surface and potentially seeping into the wood. Regular care and attention to the cleaning products you use will go a long way in preserving the sealed surface of your butcher block countertops.

Common Mistakes to Avoid

One of the most common mistakes people make when sealing butcher block countertops is not sanding the surface properly beforehand. Skipping this step can lead to a rough, uneven finish, and the sealer may not penetrate the wood evenly. Always take the time to sand the surface thoroughly and clean up all the dust before applying the sealer.

Another mistake is using the wrong type of sealer for your intended use. Some sealers, like polyurethane, are not food-safe, so if you plan on preparing food directly on the countertop, be sure to choose a finish that is safe for food contact, such as mineral oil or tung oil.

Applying too thick of a coat is another common error. Thick layers of varnish or oil can dry unevenly, leading to a blotchy appearance. It’s better to apply several thin coats, allowing each one to dry thoroughly before moving on to the next.

Neglecting to reapply the sealer regularly is another pitfall. Over time, the protective finish will wear down, especially in areas exposed to water and heavy use. Regular maintenance is key to keeping your butcher block countertops in good condition.

Some people mistakenly assume that once their countertops are sealed, they no longer need to worry about water damage. However, even a sealed butcher block countertop is not impervious to water, so it’s important to clean up spills promptly and avoid letting water sit on the surface for extended periods.

Last, using harsh cleaners can damage the sealer, stripping it away and leaving the wood exposed. Stick to mild, natural cleaners and always dry the surface thoroughly after cleaning.

How often should I reseal my butcher block countertops?

The frequency of resealing depends on the type of finish you use and how often you use the countertop. For oil-based finishes, resealing every few months is recommended, especially in high-use areas. For varnish-based finishes, resealing may only be needed every few years. Regularly check the condition of the finish and reapply when you notice it starting to wear down.

Can I use my butcher block countertops for food prep after sealing?

Yes, if you use a food-safe finish such as mineral oil or tung oil, you can safely use your butcher block countertops for food preparation. Varnish-based finishes, however, are not always food-safe, so if you plan to prepare food directly on the surface, choose an oil-based sealer instead.

What is the best sealer for butcher block countertops?

The best sealer depends on how you plan to use your countertops. If you will be preparing food on the surface, a food-safe oil such as mineral oil or tung oil is the best choice. If the countertops are more for aesthetic purposes, a varnish-based sealer like polyurethane can provide excellent protection.

Can I change the color of my butcher block countertops when sealing them?

Yes, you can use tinted oils or stains to change the color of your butcher block countertops. Be sure to test the color on a small, inconspicuous area before applying it to the entire surface to ensure you get the desired result. After staining, seal the countertop with a clear finish to protect the wood.

How do I clean sealed butcher block countertops?

Use a mild cleaner, such as diluted vinegar or gentle dish soap, to clean sealed butcher block countertops. Avoid harsh chemicals that can damage the sealer. Always dry the surface thoroughly after cleaning to prevent water from sitting on the wood.

What should I do if my butcher block countertop gets damaged after sealing?

If your butcher block countertop gets scratched or damaged, you can usually repair it by sanding the damaged area and reapplying the sealer. For deeper scratches or gouges, you may need to fill them with wood filler before sanding and resealing. Regular maintenance and prompt repair of any damage will help keep your countertops looking their best.

how to seal butcher block countertops

How to Seal Butcher Block Counters – The Chronicles of Home

Related articles:

- Butcher Block Countertops Decor

- Butcher Block Countertops Cottage

- Stain Butcher Block Countertops

- Butcher Block Countertops Vintage

- Butcher Block Countertop Farmhouse Sink

- Mahogany Butcher Block Countertops

- Butcher Block Countertop For Kitchen Island

- Can You Paint Butcher Block Countertops

- Butcher Block Countertops With White Cabinets

- Pine Butcher Block Countertops