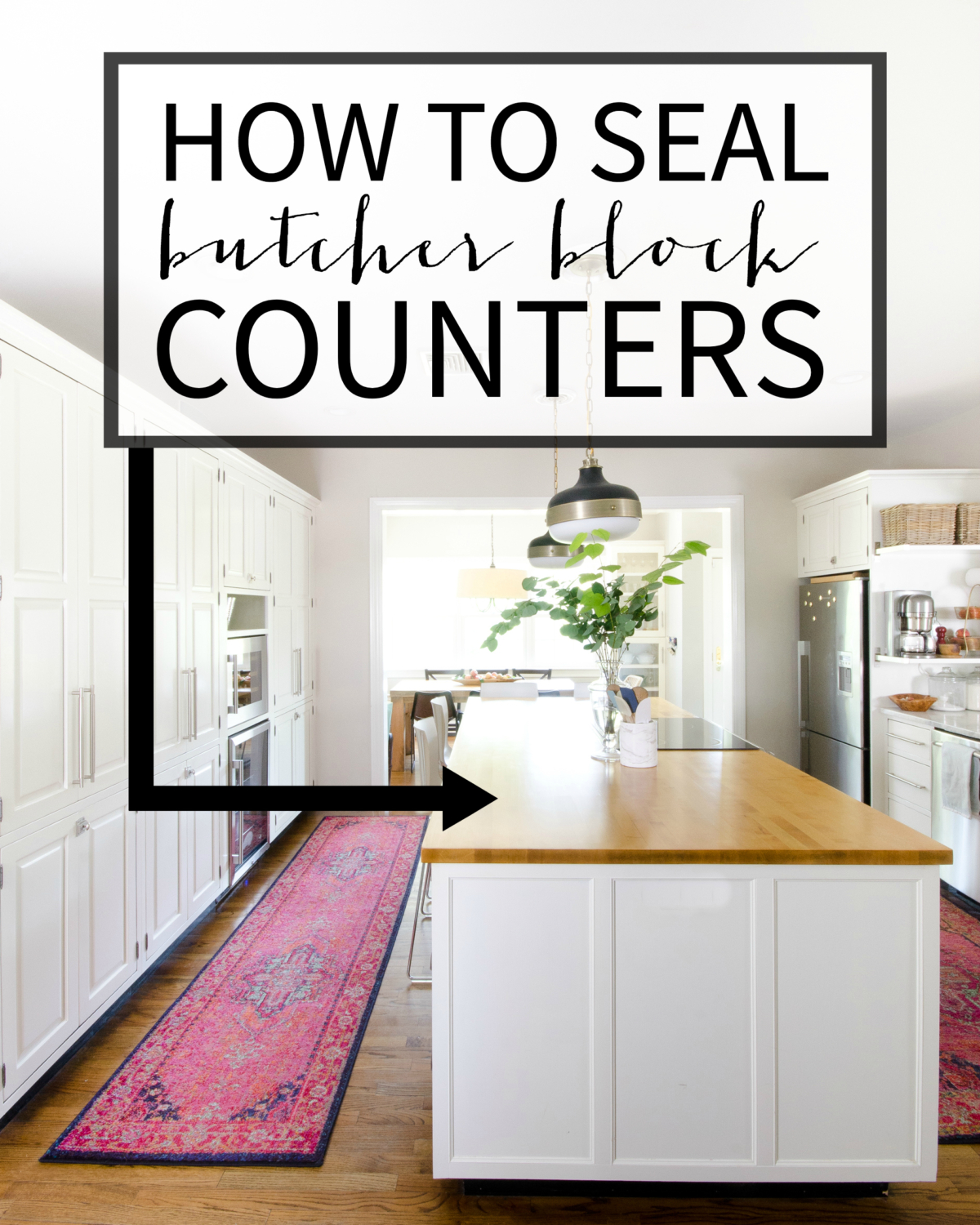

Butcher block countertops have gained immense popularity for their rustic and natural appeal in modern kitchen designs. These countertops are made from wooden planks that are glued together to create a sturdy, functional, and beautiful surface. However, as wood is a porous material, it requires special care and maintenance to ensure its longevity. One crucial aspect of this maintenance is the use of a proper sealant. In this comprehensive discussion, we will delve into the world of butcher block countertop sealants, exploring their importance, types, application, and the factors you should consider when choosing the right one.

Sealing butcher block countertops is not just a matter of aesthetics but also one of practicality. The sealant forms a protective barrier that prevents moisture, stains, and bacteria from penetrating the wood. It’s like a shield for your countertop, ensuring it remains hygienic and looking its best. Without proper sealing, wood can become damaged over time, and it may start to harbor germs and bacteria, which is far from ideal in a kitchen environment where hygiene is paramount.

When it comes to choosing a sealant for your butcher block countertop, there are various options available, each with its own set of advantages and disadvantages. One of the most commonly used sealants for butcher block countertops is mineral oil. This food-grade mineral oil is safe for direct contact with food and is excellent for enhancing the wood’s natural color and grain. It’s a simple, affordable, and effective option for sealing your countertop. However, it does require regular reapplication, especially in the initial stages, to ensure your countertop remains adequately protected.

Another popular choice for sealing butcher block countertops is a mixture of mineral oil and beeswax. This blend offers the advantages of both components. The mineral oil penetrates the wood, while the beeswax creates a protective layer on the surface. This combination provides a good balance between durability and ease of maintenance. Beeswax also adds a subtle sheen to the countertop, enhancing its visual appeal.

For those seeking a more permanent solution, there are polyurethane sealants. These sealants form a hard, water-resistant surface that can last for years without the need for frequent reapplication. Polyurethane is a popular choice for homeowners who want a low-maintenance countertop. However, it’s important to note that polyurethane sealants create a film on the surface, which can alter the natural look and feel of the wood. Some people prefer this glossy finish, while others may find it less appealing.

If you’re looking for a sealant that combines the durability of polyurethane with a more natural appearance, you might consider a water-based acrylic sealant. These sealants create a clear, matte finish that protects the wood while preserving its natural look. They are also relatively easy to apply and maintain, making them a popular choice for DIY enthusiasts.

On the other hand, if you’re open to exploring more traditional options, you might consider using a sealant made from a mixture of boiled linseed oil and beeswax. This combination has been used for generations to protect and enhance wooden surfaces. It creates a warm, amber-hued finish that can give your butcher block countertop a classic, timeless appearance. However, it’s worth noting that linseed oil takes longer to dry and harden compared to other sealants, so you’ll need to exercise patience during the curing process.

When applying sealant to your butcher block countertop, it’s crucial to follow the manufacturer’s instructions carefully. Proper application ensures that the sealant penetrates the wood and forms an effective protective barrier. In most cases, you’ll need to sand the countertop before applying the sealant to create a smooth and even surface. After sanding, wipe away any dust or debris before applying the sealant.

One common misconception when it comes to sealing butcher block countertops is that more is better. However, applying excessive sealant can lead to problems such as a gummy or sticky surface. It’s essential to use the right amount of sealant and spread it evenly across the wood. Multiple thin coats are usually more effective than a single thick one. Allow each coat to dry thoroughly before applying the next.

Another factor to consider is the curing time. Depending on the type of sealant you use, it may take several hours or even days for the countertop to fully cure and become safe for use. During this time, it’s important to avoid placing heavy objects on the countertop or using it for food preparation to prevent any damage or imperfections in the finish.

Choosing the right butcher block countertop sealant depends on your personal preferences, maintenance routine, and how you want your countertop to look and feel. If you prefer a natural, matte finish and are willing to do regular upkeep, mineral oil or a mineral oil and beeswax mixture may be the way to go. For a low-maintenance, glossy finish, polyurethane might be your best choice. Water-based acrylic sealants offer a compromise between the two. And if you’re drawn to the timeless charm of traditional sealants, linseed oil and beeswax could be the perfect fit.

Watco 241758 Butcher Block Oil u0026 Finish, Clear

How to Seal Butcher Block Counters – The Chronicles of Home

SEALING BUTCHER BLOCK COUNTERTOPS –

How to Finish and Install Butcher Block Countertop – Cherished Bliss

how to seal butcher block countertops

How to Seal Butcher Block Counters – The Chronicles of Home

Choosing a Wood Countertop Sealer – J. Aaron

Related articles:

- Butcher Block Countertops With White Cabinets

- Pine Butcher Block Countertops

- Butcher Block Countertops Walnut

- Maple Butcher Block Countertops

- Care Of Butcher Block Countertop

- Butcher Block Countertops Maintenance

- Antique Butcher Block Countertops

- Butcher Block Countertop Sealing

- Wood Butcher Block Countertop

- Thick Butcher Block Countertop