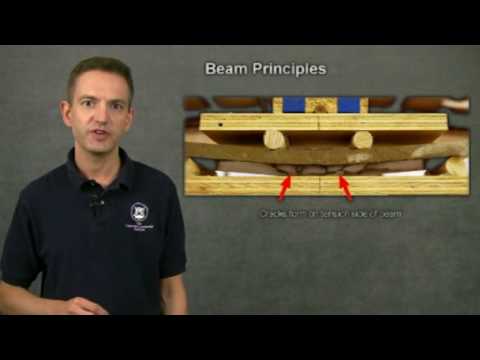

Reinforcing concrete countertops is a crucial step in ensuring their structural integrity and longevity. While concrete is a durable material, adding reinforcement helps mitigate the risk of cracking and enhances the overall strength of the countertop. The reinforcement process typically involves incorporating materials like steel mesh or fibers into the concrete mix. This additional support helps distribute the load more evenly, reducing the likelihood of hairline cracks or other forms of damage that can occur over time.

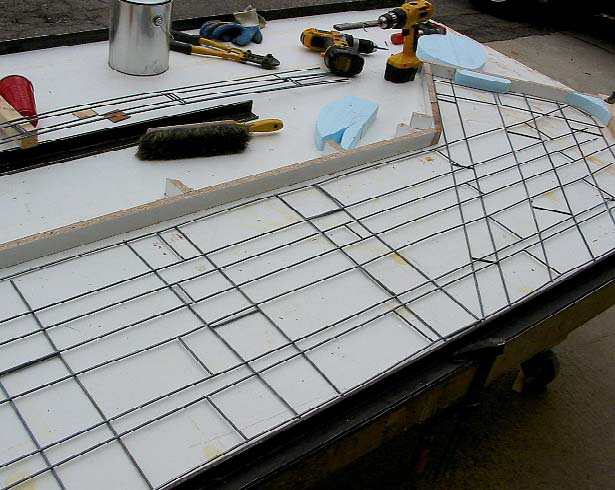

Steel mesh is a common choice for reinforcing concrete countertops. This mesh, often made of galvanized steel, is placed within the concrete mix during the casting process. The steel mesh provides tensile strength to the concrete, which is particularly important as concrete alone is strong in compression but weak in tension. The mesh helps counteract the forces that can lead to cracks, ensuring the countertop remains stable and resilient under various conditions.

Fibers are another popular reinforcement option for concrete countertops. These fibers, commonly made of materials like glass, synthetic polymers, or steel, are mixed into the concrete to enhance its tensile strength. Fiber reinforcement is advantageous as it disperses throughout the entire countertop, providing consistent support. The fibers also offer an added benefit of reducing the potential for shrinkage cracks that can occur during the curing process.

The placement of reinforcement within the concrete mix is a critical consideration. Achieving a uniform distribution of steel mesh or fibers ensures that the entire countertop receives adequate support. This careful placement minimizes the risk of weak points that could compromise the structural integrity of the countertop. Attention to detail during the mixing and casting stages is essential to guarantee a well-reinforced concrete countertop.

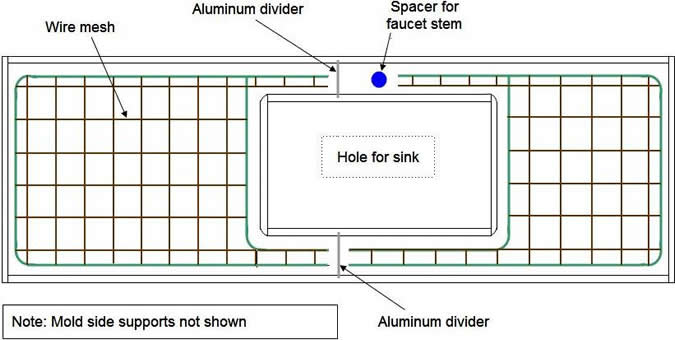

In addition to preventing cracks, reinforcing concrete countertops is essential for supporting the weight of heavy appliances, such as stoves or sinks, that may be installed on the countertop surface. The reinforcement provides the necessary strength to bear the load without sagging or deforming over time. This is particularly important in kitchen settings where countertops are subject to heavy use and various types of equipment.

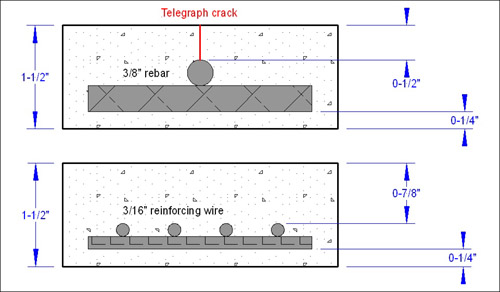

The thickness of the concrete countertop also plays a role in its overall strength. Thicker countertops generally have a greater capacity to support heavy loads. When reinforcing the countertop, the thickness should be considered in conjunction with the type and amount of reinforcement used to ensure optimal strength and stability. This careful balance contributes to the countertop’s ability to withstand the rigors of daily use.

While reinforcing concrete countertops is vital for strength, proper curing is equally important. The curing process allows the concrete to achieve its maximum strength and durability. Adequate curing time, typically a few weeks, ensures that the countertop reaches its full potential and is less susceptible to cracking or other forms of deterioration. Proper curing practices involve maintaining consistent moisture levels and protecting the countertop from extreme temperature fluctuations.

In some cases, additional considerations may be necessary based on the specific environment in which the concrete countertop will be installed. Factors such as exposure to extreme temperatures, humidity levels, or potential seismic activity can impact the choice of reinforcement materials and methods. Tailoring the reinforcement strategy to the unique conditions of the installation site enhances the countertop’s performance and longevity.

It’s worth noting that while reinforcement significantly reduces the risk of cracks, no concrete countertop is entirely immune to them. Hairline cracks may still occur due to factors like settling of the building or minor shifts in the substrate. However, proper reinforcement minimizes the severity of these cracks, preventing them from compromising the structural integrity of the countertop or affecting its functionality.

Reinforcing concrete countertops not only contributes to their strength but also allows for more creative and flexible design options. With the right reinforcement strategy, homeowners can confidently explore thinner profiles, longer spans, and unique shapes without sacrificing durability. This flexibility in design is particularly advantageous for those seeking a customized and aesthetically pleasing countertop solution that meets both functional and decorative requirements.

Reinforcing concrete countertops is a fundamental step in ensuring their durability and resilience. The use of steel mesh or fibers provides essential tensile strength, reducing the risk of cracks and supporting the countertop under heavy loads. Careful consideration of reinforcement materials, placement, and curing practices is crucial to achieving a well-reinforced concrete countertop that not only withstands the test of time but also offers design versatility for a range of applications.

Images Related to Reinforcing Concrete Countertops

What is the Right Amount of Reinforcement for a Concrete

Rebar Size in Concrete Countertops – Free Training

Concrete Countertops FAQ – Fine Homebuilding

Concrete Countertops: How reinforcing works

Rebar and wire mesh reinforcement for your concrete countertop

A Carpenteru0027s First Time Building Concrete Countertops Pro Remodeler

What is the Right Amount of Reinforcement for a Concrete

Related articles:

- Concrete Countertop Overlay

- Black Concrete Countertops

- Marble Look Concrete Countertops

- Light Grey Concrete Countertops

- Concrete Countertop Design Ideas

- Light Colored Concrete Countertops

- Epoxy On Concrete Countertop

- Concrete Countertops Designs

- Concrete Countertops That Look Like Wood

- White Concrete Countertops