Granite countertops are a popular choice for kitchens and bathrooms due to their natural beauty, durability, and unique patterns. However, one of the considerations when installing granite countertops is the presence of seams. Seams are the joints where two pieces of granite meet. While some homeowners prefer seamless countertops, in many cases, seams are unavoidable, especially in larger installations or when working with particularly intricate designs. Understanding how seams work, their appearance, and how to minimize their visibility can help homeowners make informed decisions when choosing granite countertops.

Seams in granite countertops are often necessary due to the size limitations of granite slabs. Granite is a natural stone, and slabs are quarried in specific sizes. If a countertop requires a surface larger than the largest available slab, multiple pieces must be joined together. The location of seams can also be influenced by the layout of the kitchen or bathroom, including the placement of sinks, cooktops, and other fixtures. Additionally, the design and pattern of the granite can dictate where seams should be placed to minimize disruption to the stone’s natural veining and patterns.

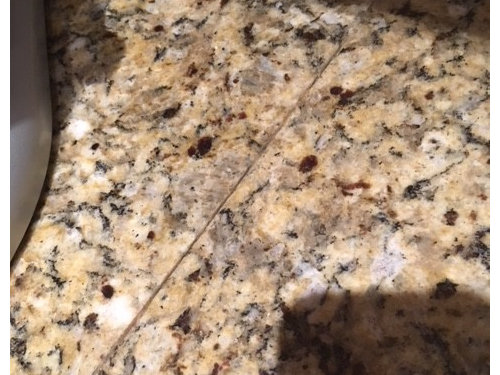

The quality and visibility of seams can vary significantly based on several factors. One of the most important factors is the skill of the fabricator and installer. A skilled professional can match the color and pattern of the granite as closely as possible, making the seam less noticeable. They will also use techniques such as book-matching, where adjacent pieces are cut from the same part of the slab and arranged to mirror each other, creating a more seamless appearance. The type of adhesive and the quality of the seam fill can also affect the final look. Color-matched epoxy is commonly used to bond the pieces together and fill any gaps, helping to blend the seam with the rest of the countertop.

Another factor affecting the visibility of seams is the finish of the granite. Polished granite tends to show seams more than honed or matte finishes because the high gloss highlights any differences in the stone’s surface. Honed finishes, with their more muted look, can help to obscure seams. Additionally, the color and pattern of the granite play a role. Darker granites with busy patterns are more forgiving of seams, as the natural variations in the stone can help to camouflage the joints. In contrast, lighter-colored granites or those with more uniform patterns may show seams more readily.

Placement of the seams is crucial for both aesthetic and functional reasons. Ideally, seams should be placed in less conspicuous areas, such as near sinks, cooktops, or corners, where they are less likely to be noticed. It is also important to consider the functionality of the countertop. Seams should not be placed in high-stress areas, such as directly over dishwashers or under heavy appliances, as this could lead to cracking or separation over time. When planning the layout, it is advisable to discuss potential seam locations with the fabricator to find the most visually and structurally suitable positions.

Proper maintenance and care of granite countertops can help maintain the integrity and appearance of the seams. While granite is a durable and hard stone, it can still be susceptible to chipping and cracking if not properly maintained. It is essential to use cutting boards and trivets to protect the surface and to avoid placing heavy items directly on the seams. Regular cleaning with a mild detergent and water, along with periodic sealing, can help protect the granite and the seams from stains and damage. If a seam becomes damaged or noticeable over time, professional repair or refinishing may be necessary to restore the countertop’s appearance.

The decision to have seams in granite countertops often comes down to balancing aesthetic preferences with practical considerations. While some homeowners prefer the look of seamless countertops, others may not mind the presence of seams, especially if they are skillfully done and not overly visible. It is important to communicate your preferences with the fabricator and installer, as their expertise can guide you in achieving the best possible outcome. They can provide samples and examples of previous work to help you visualize how the seams might look in your space.

Granite countertops with seams can still offer a stunning, high-end look, especially when the seams are well-executed. The unique patterns and colors of granite make each countertop a one-of-a-kind piece, and the natural beauty of the stone can often overshadow the presence of seams. Moreover, granite remains one of the most sought-after materials for countertops due to its durability, heat resistance, and ease of maintenance. With the right care, granite countertops can last a lifetime, making them a worthwhile investment for any home.

In terms of cost, the presence of seams does not typically affect the overall price of granite countertops. The cost is usually determined by the quality and rarity of the stone, the complexity of the installation, and the size of the project. However, the skill level required to create less visible seams can influence labor costs. Highly skilled fabricators who can minimize seam visibility may charge a premium for their expertise. It is worth investing in experienced professionals to ensure a high-quality installation, as poorly executed seams can detract from the beauty and value of the countertop.

While the presence of seams is sometimes seen as a drawback, it is important to remember that they are a common and often necessary aspect of granite countertops. In many cases, the beauty and durability of granite outweigh the concerns about seams. Additionally, advances in fabrication techniques and tools have made it possible to achieve nearly invisible seams, even with complex patterns and colors. By working with experienced fabricators and choosing the right stone, homeowners can achieve the look they desire while enjoying the many benefits of granite countertops.

Finally, it is essential to manage expectations when it comes to granite countertop seams. No matter how skilled the fabricator, seams will never be completely invisible. They are a natural part of working with a material like granite, which has inherent variations in color and pattern. Understanding this can help homeowners appreciate the craftsmanship involved in creating a beautiful countertop with well-executed seams. Properly set expectations also help in making informed decisions about the stone selection and the layout of the countertops.

Common Mistakes to Avoid

One common mistake when dealing with granite countertop seams is not thoroughly discussing seam placement with the fabricator. Homeowners should be actively involved in the planning stage to ensure seams are placed in the least conspicuous areas and away from high-stress points.

Another mistake is underestimating the importance of choosing the right fabricator. The quality of the seams heavily depends on the skill and experience of the professional handling the stone. It’s crucial to research and select a fabricator with a strong track record and good reviews.

Neglecting to consider the impact of the granite’s color and pattern on seam visibility is another error. Choosing a stone with a busy pattern or darker color can help camouflage seams, while lighter or more uniform stones may make seams more noticeable.

Additionally, homeowners should not overlook the maintenance required to keep seams in good condition. Regular cleaning, avoiding heavy impacts, and using cutting boards are essential practices. Finally, setting unrealistic expectations about the visibility of seams can lead to disappointment. Understanding that seams, while potentially minimized, will not be entirely invisible is key to satisfaction with the final result.

Are seams in granite countertops avoidable?

Seams are often unavoidable in granite countertops, especially for large surfaces or complex layouts. Granite slabs have size limitations, so if a countertop exceeds the size of the largest slab, multiple pieces must be joined. While some smaller countertops can be fabricated without seams, most installations will require them. The key is to minimize their visibility and place them in less noticeable areas. By working with an experienced fabricator and carefully selecting the granite slab, homeowners can achieve a beautiful countertop with well-executed seams that blend seamlessly into the stone’s natural patterns.

How can I make granite countertop seams less noticeable?

To make granite countertop seams less noticeable, choose a stone with a busy pattern or darker color, as these tend to camouflage seams better than lighter or uniform stones. Skilled fabricators can also employ techniques like book-matching, where adjacent pieces mirror each other, to create a more seamless appearance. The use of color-matched epoxy in the seams can help blend the joints with the rest of the countertop. Additionally, opting for a honed or matte finish can reduce the visibility of seams compared to a polished finish. Proper seam placement, such as near sinks or in corners, can further minimize their impact.

What maintenance is required for granite countertop seams?

Maintaining granite countertop seams involves regular cleaning and care. Use a mild detergent and water to clean the seams, and avoid abrasive cleaners that could damage the stone or the adhesive. It’s important to avoid placing heavy objects directly on the seams to prevent stress or cracking. Use cutting boards and trivets to protect the surface. Periodically, granite countertops may require resealing, depending on the stone’s porosity. Resealing helps protect the stone and the seams from stains and moisture damage. If any damage or separation occurs at the seams, professional repair may be necessary to restore the countertop’s appearance.

How do fabricators ensure high-quality seams in granite countertops?

Fabricators ensure high-quality seams in granite countertops through meticulous planning, precise cutting, and careful installation. They start by measuring and templating the countertop area to determine the best layout and seam placement. Skilled fabricators use advanced cutting equipment to ensure precise edges that fit together seamlessly. During installation, they use color-matched epoxy to bond the pieces and fill any gaps, carefully smoothing and blending the seam. Techniques like book-matching or vein-matching are used to align patterns and minimize the visual impact of the seam. The final polishing and finishing processes help to further blend the seam into the surrounding stone.

Can existing granite countertop seams be repaired or improved?

Yes, existing granite countertop seams can often be repaired or improved. If seams have become more visible due to wear, damage, or poor initial installation, a professional can assess the situation and recommend solutions. This may involve re-polishing the seam, reapplying epoxy, or even adjusting the pieces if possible. In some cases, additional work may be required to blend the seam more effectively with the surrounding stone. It’s essential to consult with an experienced stone fabricator or repair specialist to determine the best course of action based on the specific issues and the type of granite.

Are there alternatives to granite that have fewer or less visible seams?

While granite is a popular choice, some alternatives may offer fewer or less visible seams. Engineered stone, such as quartz, is a popular option that often comes in larger slabs, reducing the need for seams. Quartz surfaces are also more uniform in color and pattern, which can help minimize the visibility of seams. Solid surface materials, like Corian, are another alternative that can be fabricated with virtually invisible seams. These materials can be molded and joined with seamless adhesives, offering a smooth, continuous appearance. However, each material has its own advantages and considerations, so it’s important to weigh these against your specific needs and preferences.

Not all granite seams are created equal. Are your seams done right?

Granite Countertop Seams are NOT Created Equal – Stone Fabrication

Proper Seam Repairs On Granite Countertops – Pinnacle Stone Care

Related articles:

- Granite Countertop Overlay

- Stains On Granite Countertops

- Black Pearl Granite Countertops

- Black Matte Granite Countertop

- Black Granite Kitchen Countertops

- Cutting Granite Countertops DIY

- Gray Granite Countertops

- Blue Gray Granite Countertops

- Granite Countertops Wood Island

- Backsplash Ideas For Granite Countertops