Engineered quartz countertops have quickly become one of the most popular choices for kitchen and bathroom surfaces, and it’s easy to understand why. Made from a blend of natural quartz, resins, and pigments, engineered quartz offers a durable and aesthetically pleasing alternative to natural stone. Unlike granite or marble, which are quarried directly from the earth, engineered quartz is manufactured, allowing for more consistency in color and pattern. This type of countertop provides the look of natural stone with added benefits such as increased strength, durability, and a wide range of design options.

One of the primary reasons homeowners opt for engineered quartz countertops is their durability. Quartz is one of the hardest minerals on earth, ranking just below diamonds on the Mohs hardness scale. When combined with resins, it becomes even more durable, making it resistant to chipping, cracking, and scratching. This makes it an excellent choice for high-traffic areas like kitchens and bathrooms where countertops endure constant use. Unlike natural stones, which can have weak points or fissures, engineered quartz is non-porous and less likely to develop cracks over time.

A key advantage of engineered quartz over natural stone is its non-porous nature. Because the surface doesn’t have pores, it doesn’t absorb liquids, making it highly resistant to staining. This is particularly important in the kitchen, where spills from coffee, wine, or acidic foods can easily stain porous materials like marble or granite. The non-porous surface also means that engineered quartz countertops are more hygienic, as they do not harbor bacteria or viruses as easily as porous materials. This makes cleaning and maintenance much simpler and ensures a cleaner, healthier environment.

In terms of maintenance, engineered quartz is relatively low-maintenance compared to other countertop materials. It doesn’t require regular sealing or polishing as natural stone surfaces do, and cleaning is easy with just soap and water. Additionally, its resistance to staining and scratching means that you won’t have to worry about constant upkeep. This is one of the reasons why engineered quartz is a popular choice for busy households where convenience and ease of use are priorities. While it’s important to avoid harsh chemicals and abrasive cleaners, the general upkeep for quartz countertops is straightforward and manageable.

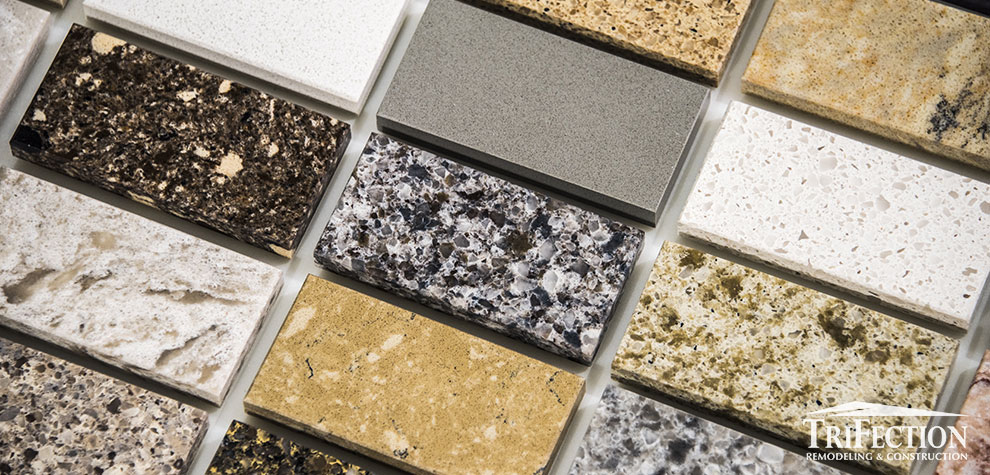

Design flexibility is another major selling point for engineered quartz countertops. Because the material is manufactured, it can be produced in a wide variety of colors, patterns, and finishes. This allows homeowners to find a style that perfectly complements their space, whether they’re looking for a natural stone look or something more modern and sleek. Quartz countertops can mimic the appearance of materials like marble or granite while offering enhanced performance. The consistent patterns and colors also mean that what you see is what you get, without the variations that can occur with natural stone slabs.

When it comes to installation, engineered quartz countertops offer some advantages over natural stone as well. Quartz countertops are typically fabricated and installed in large slabs, reducing the number of seams and providing a smooth, continuous surface. The material is also easier to work with during the installation process because it is more uniform and predictable than natural stone, which can have irregularities. This means that quartz countertops often result in a cleaner, more polished final look with fewer imperfections compared to natural stone.

While engineered quartz countertops are incredibly durable, there are some limitations to be aware of. The resins used in quartz countertops can be sensitive to extreme heat. While the material is heat-resistant to a degree, placing hot pots or pans directly on the surface can cause discoloration or damage. It’s recommended to use trivets or heat pads to protect the countertop from high temperatures. However, quartz is still more resistant to heat than materials like laminate, making it a better option for kitchen use.

Another factor to consider is that engineered quartz countertops can be heavier than other materials. Quartz is dense and, when combined with resin, can make for a heavy slab. This means that proper support is needed for installation, especially for larger countertops or overhangs. Cabinets and surfaces must be strong enough to support the weight of the quartz to avoid sagging or cracking. While this doesn’t typically pose a problem for most modern cabinetry, it’s something to consider if you’re working with older or less sturdy structures.

The environmental impact of engineered quartz countertops is worth discussing as well. Quartz is a natural material, but the manufacturing process of engineered quartz involves energy-intensive procedures and the use of synthetic resins. However, many quartz manufacturers are making strides toward sustainability by using recycled materials and improving energy efficiency in production. Some companies also offer eco-friendly options that contain a high percentage of recycled content, making them a greener choice for environmentally conscious homeowners.

Cost is another important consideration when choosing countertops. Engineered quartz tends to be more affordable than high-end natural stones like marble, but it’s still on the pricier side compared to materials like laminate or tile. However, the cost of engineered quartz is often justified by its durability, longevity, and low maintenance requirements. Additionally, since quartz is non-porous and doesn’t require sealing, you’ll save money over time compared to materials that need regular upkeep. For many homeowners, the initial investment in quartz pays off in the long run through its resilience and ease of care.

Quartz countertops have become a staple in modern kitchen design due to their sleek appearance and adaptability to various styles. Whether you’re designing a contemporary kitchen with clean lines and neutral colors or a more traditional space with rich textures and patterns, quartz can complement your design. The material’s versatility allows it to seamlessly integrate with different aesthetics, and the wide range of color and pattern options makes it easy to find a style that matches your vision.

In addition to kitchens, engineered quartz is an excellent choice for bathroom countertops. Its resistance to moisture and stains makes it particularly well-suited for bathroom use, where countertops are exposed to water, soap, and various grooming products. Quartz’s non-porous surface ensures that it won’t absorb moisture or develop mold and mildew, which is a common issue with more porous materials. Plus, its durability means it can withstand daily wear and tear without losing its luster.

One of the concerns some homeowners have when considering engineered quartz is its authenticity compared to natural stone. While quartz can replicate the look of natural materials like marble, some people worry that it lacks the unique beauty and character of real stone. However, advances in quartz manufacturing have made it possible to produce countertops that closely resemble the veining and texture of natural stone, often with added benefits in terms of consistency and performance. For many, the trade-off between natural and engineered stone comes down to personal preference and lifestyle needs.

Another benefit of engineered quartz is that it’s more resistant to chemical etching compared to materials like marble. Acidic substances such as lemon juice, vinegar, and certain cleaning products can damage marble by leaving dull spots or etch marks. Quartz, however, is much less susceptible to this type of damage, making it a more practical choice for households where spills and messes are common. This makes quartz particularly appealing for busy kitchens or homes with young children.

For those concerned about the long-term value of their home, installing engineered quartz countertops can be a smart investment. Quartz countertops are highly sought after in the real estate market due to their durability, aesthetic appeal, and low maintenance requirements. Upgrading to quartz can increase the overall value of your home and make it more attractive to potential buyers. Since quartz is a timeless material that works with various design styles, it’s likely to remain in demand for years to come.

Common Mistakes to Avoid

One common mistake when installing engineered quartz countertops is not ensuring proper support for the slabs. Quartz is a heavy material, and if the cabinets or surfaces below the countertop aren’t strong enough, it can lead to sagging or cracks over time. Be sure to reinforce the structure as needed, particularly for large countertops or overhangs.

Another mistake is using harsh cleaners or abrasive scrubbing tools on the quartz surface. While quartz is durable, it can still be scratched or damaged by abrasive materials. Stick to gentle cleaning solutions like mild soap and water, and avoid products that contain bleach or other harsh chemicals.

Some homeowners also make the mistake of placing hot pots or pans directly on quartz countertops. While quartz is heat-resistant to a degree, it’s not impervious to heat damage. Always use trivets or heat pads to protect the surface from high temperatures to avoid discoloration or damage to the resin.

Not sealing the seams between slabs properly can lead to issues down the road. While quartz itself doesn’t need sealing, the seams between slabs can be a weak point if not installed correctly. Make sure your installer pays close attention to sealing and leveling the seams for a seamless appearance and to prevent moisture from getting underneath.

Failing to choose the right thickness for your quartz countertops is another mistake. The standard thickness for countertops is usually around 1¼ inches, but thinner slabs are available. While thinner slabs can be used for aesthetic reasons, they may require additional support to prevent damage.

Lastly, rushing the installation process can lead to mistakes. Ensure that measurements are accurate and that the quartz is cut and installed with precision. Any errors in cutting or measuring can be difficult to fix after the fact and may compromise the look and functionality of the countertop.

What is the difference between engineered quartz and natural stone countertops?

Engineered quartz is a manufactured product made from natural quartz crystals, resins, and pigments, while natural stone countertops, like granite or marble, are quarried directly from the earth. Quartz offers more consistency in color and pattern, as well as improved durability and resistance to staining. Natural stone, on the other hand, may have unique variations and requires more maintenance, such as regular sealing.

Are engineered quartz countertops heat-resistant?

Yes, engineered quartz countertops are heat-resistant to a degree, but they are not heatproof. The resins used in quartz can be damaged by extreme heat, so it’s recommended to use trivets or heat pads when placing hot items like pots or pans on the surface. This will help prevent discoloration or damage to the resin.

Do engineered quartz countertops need to be sealed?

No, engineered quartz countertops do not require sealing. The manufacturing process makes quartz non-porous, which means it doesn’t absorb liquids or harbor bacteria. This is one of the major benefits of quartz over natural stone countertops, which typically need to be sealed regularly to protect against stains and moisture.

Can quartz countertops stain?

Engineered quartz countertops are highly resistant to staining because of their non-porous nature. However, while they are resistant to stains, they are not completely stain-proof. Prolonged exposure to certain substances like wine, coffee, or oils may leave marks if not cleaned up promptly. Fortunately, most spills can be cleaned easily with soap and water.

How do I clean and maintain engineered quartz countertops?

Cleaning engineered quartz countertops is simple and requires just mild soap and water for daily maintenance. Avoid using harsh chemicals or abrasive cleaners, as these can damage the surface. Regular cleaning with a soft cloth or sponge will keep your countertops looking pristine, and you won’t need to worry about sealing or polishing them over time.

How does the cost of engineered quartz compare to other countertop materials?

Engineered quartz countertops are generally more expensive than materials like laminate or tile but less expensive than high-end natural stones like marble. The cost of quartz is typically on par with or slightly higher than granite, depending on the brand and style you choose. However, its durability, low maintenance, and long lifespan often make it a cost-effective choice in the long run.

Related articles: