When it comes to incorporating glass chips into a concrete countertop, the first step is to choose the right type of glass chips. Various options are available in size, shape, and color. I consider the overall aesthetic I want to achieve and the color scheme of my kitchen or bathroom. Glass chips come in different sizes, ranging from small shards to larger chunks, and I select the size that best suits the design and style I desire.

Additionally, I pay attention to the shape of the glass chips, whether they are irregular or more uniform, and choose accordingly. As for color, glass chips come in many hues, including transparent, translucent, and opaque options. I select glass chips that complement the color palette of my space or create a contrasting effect. It’s important to source high-quality glass chips specifically designed for use in concrete countertops to ensure their durability and longevity.

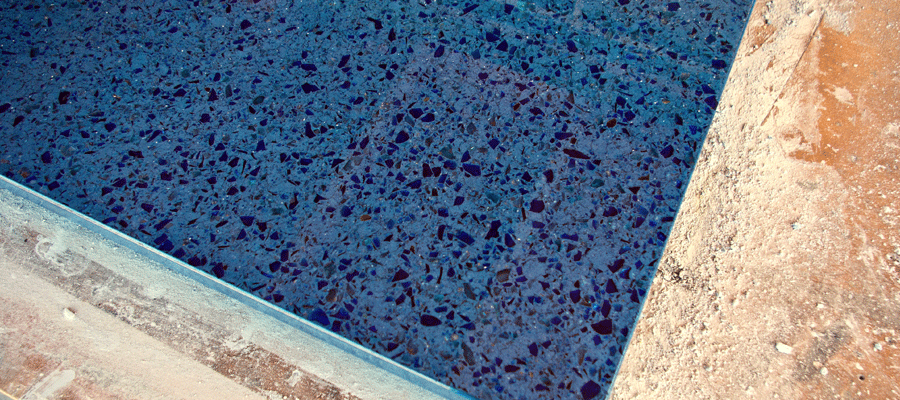

Here are Images about Concrete Countertop Glass Chips

Incorporating Glass Chips into the Concrete Mix

Once I have chosen the glass chips for my concrete countertop, I move on to incorporating them into the concrete mix. I start by preparing the concrete mix according to the manufacturer’s instructions, ensuring the desired consistency. Before adding the glass chips, I wet the surface of the countertop mold or form to create a bond between the concrete and the glass. Then, I gradually add the glass chips to the concrete mix, ensuring they are evenly distributed throughout. I mix the glass chips and concrete together using a paddle mixer or by hand, ensuring not to overmix to avoid damaging the glass chips or altering their appearance. It’s important to balance incorporating the glass chips into the concrete mix and maintaining their visibility and texture within the countertop. Once the concrete and glass chips are thoroughly mixed, I pour the mixture into the countertop mold or form, ensuring a smooth and even distribution of the material.

Embedding Glass in Outdoor Concrete Countertops – Concrete Network

Polishing and Sealing the Concrete Countertop with Glass Chips

After the concrete has cured, the next step is to polish and seal the countertop to enhance its appearance and durability while protecting the glass chips. I start by using progressively finer grits of diamond polishing pads to grind and smooth the countertop’s surface. This process gradually removes the top layer of concrete, revealing the glass chips embedded within it. I pay special attention to avoid grinding down the glass chips excessively, as I want them to be visible and add a decorative touch to the countertop. Once the desired level of smoothness and sheen is achieved, I thoroughly clean the countertop surface, removing any dust or debris.

Finally, I apply a high-quality concrete sealer specifically formulated for countertops. The sealer not only enhances the color and luster of the concrete but also protects the glass chips from wear, stains, and moisture. I follow the manufacturer’s instructions for applying the sealer, ensuring complete coverage of the countertop surface. The result is a stunning and durable concrete countertop with glass chips that add a unique and eye-catching element to my kitchen or bathroom space.

Terrazzo with blue glass aggregate Recycled glass countertops

How-To: Concrete Countertops Using Recycled Glass Aggregates

How to use Glass as Aggregate in Concrete – Concrete Decor

Make Recycled Glass Countertops CHENG Concrete Exchange

Embedding Glass in Outdoor Concrete Countertops – Concrete Network

Glass and Concrete Countertop – Contemporary – Bathroom – Tampa

Glass Aggregates Dress Up Concrete Slabs – Concrete Decor

Recycled Glass Countertops Review Countertop Specialty

Related articles:

- Concrete Countertop Overlay

- Black Concrete Countertops

- Marble Look Concrete Countertops

- Light Grey Concrete Countertops

- Concrete Countertop Design Ideas

- Light Colored Concrete Countertops

- Epoxy On Concrete Countertop

- Concrete Countertops Designs

- Concrete Countertops That Look Like Wood

- White Concrete Countertops