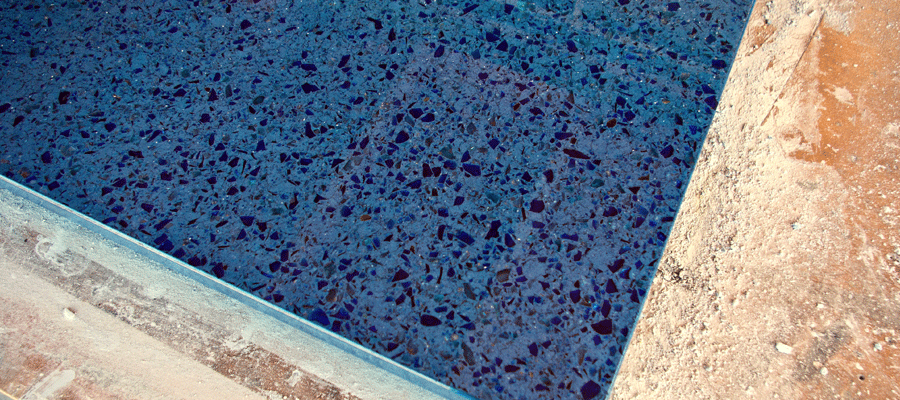

Concrete countertops with glass aggregate are a unique and visually stunning option for adding a touch of creativity and individuality to your space. Glass aggregate refers to small pieces of recycled or crushed glass that is incorporated into the concrete mix, resulting in a beautiful, translucent effect when the countertop is polished.

This technique allows for endless possibilities in terms of color, texture, and design. Glass aggregate can be sourced in various colors, including vibrant hues or subtle tones, providing the opportunity to create a customized and eye-catching countertop. The glass aggregate adds depth and character to the concrete, giving it a distinctive and contemporary appearance. By understanding the concept of concrete countertops with glass aggregate, I can explore the artistic possibilities and create a unique countertop for my space.

Concrete Countertop Glass Aggregate

To incorporate glass aggregate into a concrete countertop, careful planning and execution are essential. I begin by selecting the desired colors and sizes of the glass pieces. Depending on the desired effect, these can range from small, fine particles to larger, more noticeable chunks. When mixing the concrete, I add the glass aggregate during the blending process, ensuring that the glass pieces are evenly distributed. The amount of glass aggregate used can vary based on personal preference and design objectives. It is important to strike a balance between achieving the desired visual impact and maintaining the structural integrity of the countertop.

Once the concrete and glass aggregate is thoroughly mixed, I pour the mixture into the countertop mold, carefully leveling and smoothing the surface. Throughout the curing process, I monitor the countertop to ensure the glass aggregate is evenly distributed and that there are no air pockets or voids. Incorporating glass aggregate into the concrete mix requires attention to detail and precise execution to achieve the desired aesthetic result.

How-To: Concrete Countertops Using Recycled Glass Aggregates

After the concrete countertop with glass aggregate has fully cured, the next step is to polish and seal the surface. Polishing is a critical stage that brings out the beauty and depth of the glass aggregate. I use progressively finer grits of diamond polishing pads to achieve a smooth and glossy finish. This process gradually removes any surface imperfections and reveals the glass aggregate’s vibrant colors and unique patterns. Once the desired level of polish is achieved, I thoroughly clean the countertop to remove any dust or debris.

Finally, I apply a high-quality sealer designed for concrete countertops to protect the surface and enhance its durability. The sealer helps prevent stains and water damage, ensuring the glass aggregate remains vibrant and intact over time. By carefully polishing and sealing the concrete countertop with glass aggregate, I can enjoy a stunning and durable countertop that becomes a focal point in my space.

Make Recycled Glass Countertops CHENG Concrete Exchange

Recipe: Beach Glass Countertop – Concrete Decor

Countertop Glass Terrazzo

Embedding Glass in Outdoor Concrete Countertops – Concrete Network

How to Use Glass in Decorative Concrete Countertops – Runyon

Adding decorative aggregate to concrete countertops – Free Training

Glass Aggregates Dress Up Concrete Slabs – Concrete Decor

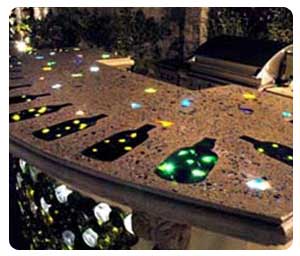

Glow in the dark concrete countertops in the Cayman Islands

Related articles:

- Concrete Countertop Overlay

- Black Concrete Countertops

- Marble Look Concrete Countertops

- Light Grey Concrete Countertops

- Concrete Countertop Design Ideas

- Light Colored Concrete Countertops

- Epoxy On Concrete Countertop

- Concrete Countertops Designs

- Concrete Countertops That Look Like Wood

- White Concrete Countertops