Concrete countertops have gained popularity in modern interior design due to their versatility and unique aesthetic appeal. One crucial aspect of the concrete countertop installation process is the curing time, which significantly influences the final durability and appearance of the surface. Curing is the process of maintaining adequate moisture, temperature, and time to allow the concrete to achieve its maximum strength and resilience.

The typical cure time for concrete countertops is approximately 7 to 14 days, but it can vary based on factors such as the specific mix design, ambient temperature, and humidity levels. During this period, the concrete undergoes chemical reactions that contribute to its long-term strength and durability. Rushing the cure time can compromise the structural integrity of the countertop and lead to issues such as cracking or surface imperfections.

Maintaining the right moisture level is crucial during the curing process. Concrete countertops are often covered with wet burlap, plastic sheeting, or other moisture-retaining materials to slow down the evaporation of water from the surface. Adequate moisture ensures that the concrete continues to hydrate and strengthen, reducing the risk of cracking and enhancing the overall quality of the countertop.

Temperature plays a significant role in the concrete curing process. Ideally, the ambient temperature should remain within a range of 50 to 90 degrees Fahrenheit. Extreme temperatures, whether too hot or too cold, can negatively impact the curing process. Cold temperatures can slow down the chemical reactions, while excessive heat can lead to rapid evaporation of water, affecting the concrete’s strength and appearance.

In addition to ambient temperature, the temperature of the concrete mix itself is essential. Some countertop artisans use insulation blankets or heating elements to maintain a consistent temperature during the curing period. This is particularly relevant in colder climates where temperature fluctuations can impede the curing process.

The curing time is not the endpoint of the concrete countertop’s development. While the initial cure time establishes the foundation of strength, concrete continues to gain strength over an extended period. The concrete’s full curing process can take up to 28 days, with the first week being the most critical. However, even after 28 days, the concrete may continue to improve in strength gradually.

Properly cured concrete countertops exhibit enhanced resistance to stains, cracks, and surface imperfections. The curing process allows the concrete to achieve its optimal hardness, making it more resilient to daily wear and tear in the kitchen or bathroom. It also contributes to the development of a smooth and visually appealing surface.

Ensuring a thorough cure is crucial for preventing common issues like hairline cracks or surface blemishes. Rushing the process or exposing the concrete to unfavorable conditions can compromise the countertop’s quality and aesthetics. Patience during the cure time contributes significantly to the long-term satisfaction and performance of the concrete countertop.

The use of curing compounds or sealers can further enhance the curing process and protect the concrete countertop. These products help to retain moisture, regulate temperature, and provide an additional layer of protection against stains and scratches. Applying a high-quality sealer after the initial cure period is an important step in maintaining the longevity and appearance of the concrete surface.

Humidity levels in the curing environment also impact the overall curing process. In high-humidity conditions, the risk of the concrete drying out too quickly is reduced. However, in arid climates or spaces with low humidity, additional measures may be necessary to ensure adequate moisture retention, such as frequent misting or covering with wet materials.

The choice of concrete mix design influences the cure time and final characteristics of the countertop. Some mix designs incorporate additives or admixtures that accelerate or retard the curing process. Contractors and artisans can tailor the mix to meet specific project requirements, taking into consideration factors such as desired appearance, strength, and curing time.

While professionals often handle the installation of concrete countertops, some DIY enthusiasts may undertake the project themselves. DIYers must follow best practices for curing, including proper moisture retention, temperature control, and patience during the curing period. Adhering to recommended guidelines ensures a successful outcome and a durable, attractive concrete countertop.

Concrete countertop cure time is a critical phase in the installation process that significantly influences the final strength, durability, and appearance of the countertop. Patience, proper moisture retention, and temperature control during the curing period are essential for achieving the desired results. Whether installed by professionals or DIY enthusiasts, careful attention to curing practices contributes to the long-term satisfaction and performance of concrete countertops in residential and commercial spaces.

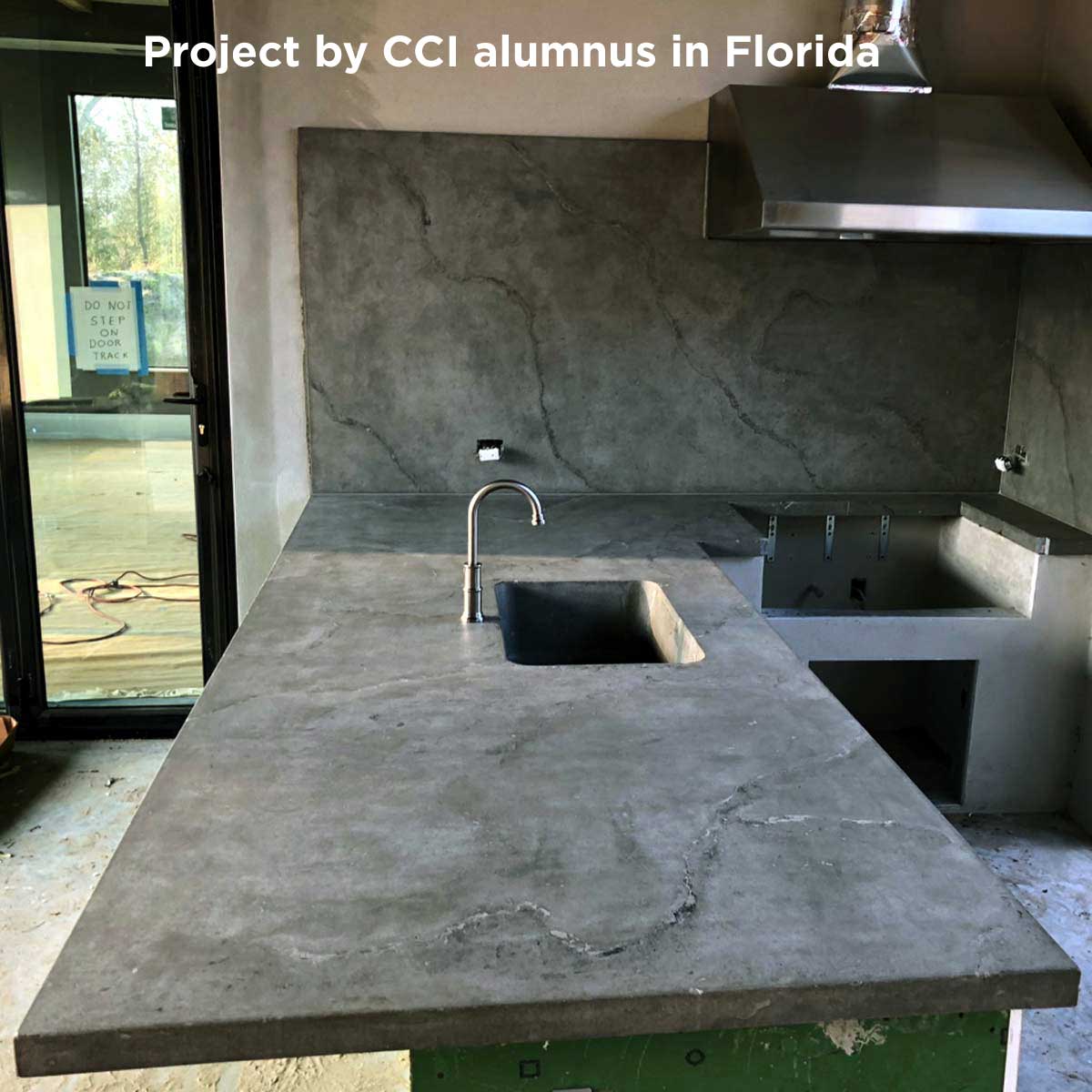

Images Related to Concrete Countertop Cure Time

How to Build a Concrete Countertop HGTV

How to Finish Concrete Counters Real Milk Paint

Concrete Countertop DIY – A Beautiful Mess

Concrete Countertops FAQ – Fine Homebuilding

Omega Pro Concrete Countertop Sealer Concrete Countertop Institute

Benefts of Quikrete Countertop Mix – Concrete Decor

Related articles:

- How To Stain Concrete Countertops

- DIY Concrete Countertop Mix

- Concrete Countertops Made Easy

- Concrete Countertop Overlay

- Black Concrete Countertops

- Marble Look Concrete Countertops

- Light Grey Concrete Countertops

- Concrete Countertop Design Ideas

- Light Colored Concrete Countertops

- Epoxy On Concrete Countertop